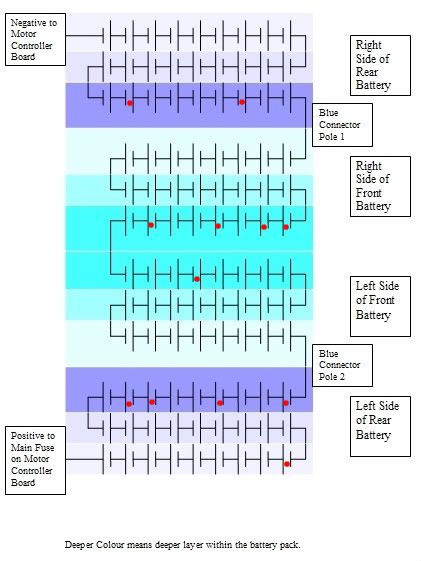

Using a discharge rate of 20A and 1.1V as cutoff voltage, the cells with a red dot had less than 19Ah capacity before reconditioning.

Darker colour signifies deeper layer inside the packs (three layers).

It is extremely unlikely that the distribution shown is due to chance.

All but one cell with lowered capacityare located in the bottom layer of cells.

Any ideas what would cause this difference in capacity?

Some starters:

Radiant heat from the road? (Australia, hot here in summer)

Bottom layer gets hit by air flow first, including aerosols like ocean salt sprays.

Physical pressure of double it's own weight on top, coupled with g-forces due to being located ina motorcycle.

Deliberate accumulation of low capacity cells in the first layer during some stage of assembly (but some of the highest capacity cells were in the bottom layers, too!)

NiMH cells are adversely affected by heat ... so I'd expect the heat related issues to be the culprit. e.g. how is the flow of cooling air in the bottom of the container? That is, I expect the container the pack sits in is sealed?

At the price Vectrix charges my expectation is they'd be careful about choosing balanced cells for the packs they sell. I would also expect weaker cells to be randomly distributed. This isn't random so the question is what made it less than random.

What are you using to make measurements? Are these measurements after you stop a ride or during a ride? Or is it with the bike on a testbench setup in your garage?

The red dots are marking ones that gave fewer AH's? Rather than ones with lower voltage?

- David Herron, The Long Tail Pipe, davidherron.com, 7gen.com, What is Reiki

It is the capacity at 20A with a 1.1V cutoff using a CBA2 on the bench. Before reconditioning.

Broadband connection is down, thumb-typing, grrrrrrr...

Must keep it short; details on ES in the Battery Tech section.

The air is forced through gaps between the cells by fans running during charging and whenriding with a battery hotter than about 36dC.

The bottom layer gets incontact with the air first.

The air leaves through the fans after it has passed through bottom, middle and top layers of the cells.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Yes, most likely heat related.

The Reduced capacity (at 20A to 1.1V cutoff)of the cells is also highly correlated with physical swelling of the cells.

All cells with less than 19Ah capacity have swollen and are located in the bottom layer of cells (except cell 103-9:it shows Tswelling+16.4Ah in top layer.)

Only two cells with higher capacity have swollen, and they are located in the middle layer.

One cell with 24Ah capacity has swelling on one side only, unlike all others which swell symmetrically.

This cell is also in the bottom layer.

I believe this is a major design fault, which leads to a reduction of battery life-expectancy by more than 50%!!

Indeed!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

The PDF file linked to below shows the original configuration of cells in the Vectux.

http://www.endless-sphere.com/forums/download/file.php?id=15767

I have added the serial numbers to analyze if there is a relationship between cell capacity, swelling and serial number / manufacturing date.

I could not see any pattern there, it seems that the uneven distribution of low-capacity cells is unrelated to the production date of the cells.

As I mentioned earlier, the low capacity cells and swollen cells were almost exclusively located in the bottom layer of three, and I believe it is radiant heat exposure from hot road surfaces that caused this, but have not tested it yet.

I plan to locate a temperature sensor below the cells (the original sensors all sit on top of the cells and miss heating up from underneath until it is too late).

If the temperature in the bottom of the battery compartment is indeed shown to be too hot on future testing, then I will paint the underside with heat reflective paint to reduce the problem.

I have marked the cells with <19Ah capacity on initial testing at 20A to 1.1V cutoff, and those with between 19Ah and 20Ah, as well as those with swelling. All those with <19Ah capacity have also swollen.

The Serial numbers have this structure: C3008 YYMMDD 00xxxx , with YYMMDD being the date of manufacture.

There is also a date of assembly for the Modules of 8 or 9 cells: M3008 YYMMDD 00xxxx .

Can anyone come up with an alternative explanation for the uneven distribution of low capacity + swollen cells?

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Although the effect is the same, I was wrong about the mechanism that causes the bottom layer cell damage!

In February and March 2009 I ran several experiments in relatively hot weather (despite the heat wave and fires down South, and the extensive flooding in the North, the summer here on the Australian Gold Coast has been mild and wet this year) and monitored the temperature of the cells (via the 12 original temp sensors in the pack) and in 6 additional locations, using the M-BMS.

It took some time to get around to look at the results and to understand them.

Here is what I got wrong:

There is massive heat transfer through the several layers of plastic at the top of the batteries! Not really much of a surprise, thinking of black plastic in full sun.....

The surface temperature of the plastic cover gets easily to 65°C in full sun, even if the air temperature is only 33°C. It can get a lot hotter here, just not this year! Although the bitumen temperature was about 50°C at the same time, the temperature rise of the top layer and middle layer cells is steeper and reaches higher top temperature than the bottom layer.

The top and middle layers will therefore discharge themselves faster and deeper than the bottom layer. This would particularly be a problem during long periods of repeated heating without riding and recharging, like in a "showroom" where the bikes are brought outside during the day to attract more attention and buyers.

The end result is a bottom layer of cells which are much fuller charged than the top 2/3 of the battery. Once an unsuspecting victim (also known as the buyer) has been found, the well meaning salesman charges the battery. The overall string voltage appears low to the BMS when in fact the bottom cells are already full and 10A continue to get pumped into the pack, leading to over-charging, overheating and venting of cells in the bottom layer.

The cruel irony is, that it actually affects the best cells in the bottom layer of the string, those cells which had the lowest self discharge rate. Because they managed to maintain a higher state of charge (SOC), they end up being over-charged and damaged!

The additional damage from reverse charging comes after the initial insult, which is over charging!

So it is more important to insulate the TOP of the scooter against heat than the bottom.

And the BMS needs to monitor each module of 8 or 9 cells, so that temperature dependent differences in self discharge rate are reliably detected and a slow equalisation charge is started. Due to the arrangement of the 3 segments monitored by the stock-BMS, it is totally blind to systematic SOC differences between layers of cells: Each segment has 1/3 top cells, 1/3 middle cells and 1/3 bottom cells.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Not to mention the fact that heat from within the battery pack itself will rise to the upper levels.

I always thought your "road heat" theory was flawed, but had nothing but my own theory to dispute it with. However, taking into account the fact that the bottom of the pack is only covered with a thin layer of aluminum, which is exposed to all the wind while riding, and shade while parked, I would certainly imagine that the bottom gets rapidly cooled, while all the heat just continues to build up in the top.

Personally, I'm just going to assume that this is all a given, and not concern myself with it. If this bike doesn't hold up long enough to at least equal it's cost in fuel savings and normal depreciation of any other vehicle I would have bought, I'll declare the technology not-quite-ready for prime time and move on. I'm hoping for the best, both for the company and my ride! :-) And in the mean time, it's just plug and play for me, and I'm enjoying the heck out of it! ;-)

Is this a case where a BMS monitoring every individual cell in the whole pack, and protecting each one from overcharging and over-discharging, would have avoided damaging the cells?

Or, does every cell have to be temperature-monitored also?

Cheers, Gary

XM-5000Li, wired for cell voltage measuring and logging.

it would probably be an either/or case

its the heat that damages Ni-MH, not the actual overcharge.

temperature monitoring would probably be easier.

doing by voltage would require identification of the voltage drop at end of charge (a bit more complicated to do than the BMS's we use for lithiums).

another alternative is to use active cooling (refridgeration), such as was used on the EV1 in place of a BMS

Matt

Daily Ride:

2007 Vectrix, modified with 42 x Thundersky 60Ah in July 2010. Done 194'000km

All it needs is voltage monitoring of each module of cells; that means 6 x 9 cell modules in the rear, and 6 x 8 cell modules in the front battery. No active balancing between cells is required; just reducing the charger output to 3A (CC mode) and running the powerful cooling impellers for as long as it takes to balance the pack would be enough. More than 12 temp sensors could also help.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

That is only correct when talking about a C/10 or less charging current.

Over-charging at C/10 causes heating up. The cooling impellers take care of that. The heating, if not too severe, causes gradual premature ageing of the cells, it slowly reduces their life expectancy. This is only significant if it happens for prolonged times or repeatedly during each charge.

Over-charging with C/3 (which is 10A for the Vectrix, the charging current during CP charging) will exceed the cells ability to recombine the resulting hydrogen and oxygen gases. The cell will still heat up, but much more importantly at C/3 the internal pressure will rise, the cell will bulge and eventually vent some of it's preciuous contents into the atmosphere through the safety valve. That will immediately and permanently reduce the capacity of the over-charged cell, even in a single event!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Here is a suggestion how to fix the problem with a software patch:

Adjust the command that tells a Vectrix to "perform an equalization charge after the next complete charge", so that the equalization charge is done instead of the normal charge. Continue this as long as necessary, i.e. until the voltage reaches about 147V and all the temp sensors report significantly elevated cell temperature compared to air temperature.

The command to "perform an equalization after the next complete recharge" can apparently only be given via the scooter diagnostics software and the USB to Can data cable.

Performing a normal charge on a very imbalanced pack is a bad idea, anytime. Doing the equalization charge after the full recharge is too late, because the best cells in the pack might already have been cooked and have vented by then.

A very unbalanced pack can happen any time that the scooter has been inactive for prolonged periods, like in a showroom before sale, and after seasons too hot, too wet or too cold to ride, depending on climate zones.

Even just a few days of being parked in the sun at a train station or airport could lead to an unbalanced pack.

It might therefore be a good idea to allow the proposed "Equalization-only-charge-when-plugging-in-next-time command" to be included into the owner programmable features, like the charging delay in the later software version.

The equalization charge would just consist of a long 3A DC charge with the usual temperature and voltage safety cutoffs, plus an about 14hr timer cutoff. The impellers should probably be running throughout the equalization charge, in case some cells far from a temp sensor are full first, and begin to heat up.

I would bet there are a few people who recently lost their jobs who could write such a software patch. I'm not so convinced if there are any people still employed by Vectrix who could do it, though! I might of course be very wrong about this, just guessing, really!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

While they're patching, let's see if we can get them to replace the "Estimated Range" readout with "Current Battery Voltage". That would make way more sense than a silly "How's my driving?" gauge that really tells me nothing. ;-)

I'm looking at replacement batteries, if Vectrix goes bust and my NiMH pack fails.

I found Kokam's site and found these LiPo batteries:

http://www.kokam.com/product/product_pdf/high_power/PL-201_SLPB78216216H_31Ah_Grade.pdf

http://www.kokam.com/product/product_pdf/high_power/PL-202_SLPB100216216H_40Ah_Grade.pdf

37 cells would equate to 155.4V of maximum Voltage, so the Vectrix' charger, with cut-off Voltage of 153V, should sufficiently charge a pack of 37 LiPo cells to almost full, which is perfect, since LiPo cells life get's extended if they're not charged fully.

I'd add a balancer for 37 cells, which would balance the pack when charging and discharging.

Two questions:

1. Mik, would these (31Ah) Kokam cells fit into Vectrix battery compartment (8.4mm x 215mm x 220mm)? How about 40Ah batteries ((10.7mm x 215mm x 220mm))?

2. Are there any objections to charge a pack of 37 cells (155.4V) with Vectrix' charger? Cells can be charged with up to 62A, Vectrix charges with up to 12A. Vectrix cuts'ff charging at 153V, which is perfect for maximum voltage of 37 cells, which sums to 155.4V?

One cells weighs aprox. 860g+-40g = 33kg, which would greatly reduce the battery pack weight from 90kg, increase acceleration and lower power consumption.

An added bonus is, that my Vectrix' firmware cuts-off discharge at 105V, which is perfect for LiPOs, since their cut-off is at 2.7V = 2.7V * 37 cells = 99.9V :-)

I don't know!

They must not be bigger or smaller than this (or padding could be used):

There is practically no additional space in the battery compartment for a BMS, either!

.

Other problems are:

The charger does NOT actually charge to 153V. It's 146V or less.

153V is only a safety cutoff which gets reached when the battery is fuller than the software expects.

The cutoff voltage is not 105V, it used to be 108V and has been increased in the software updates. The current delivery to the motor was gradually reduced, until there was practically none delivered at 108V. You would want that gradual reduction gone if you have a proper BMS and all cells are up to the task.

The charger (new software versions) does an "equalization charge" every so often, this might seriously affect Li cells! It might also just fully charge them to the 149V to 153V (depending on temperature) safety voltage cutoff. Who knows?

Without the ability to reprogram the charger and MC it will be tricky.

You also have to keep the Stock-BMS happy by supplying it with voltages like in the below diagram of the Stock Vectrix voltage divider:

You must be able to break the replacement pack into sub-strings close to 48/102 + 27/102 + 27/102, otherwise the Stock BMS might see the pack as unbalanced and cause trouble somehow.

If you are serious about working on this, then you might want to start a new thread about it so others can find it more easily later on.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

If Vectrix does go bust and my NiMH pack deteriorates, I would upgrade to a new solution with a help of a fellow who converts existing ICE vehicles:

http://www.ad-pecjak.si/ECO/Ecar1.htm

I still have the old software installed, so it's 108V cut-off, which is even safer than the 105V, which is good.

My NiMH's resting pack Voltage is about 144V, but when it charges, the charging Voltage, with my Vectrix, comes to the 150-153V region.

If I had 38 cells, the division in my case would be 10+10+28, so that it doesn't think it's out of balance. It would have a permanent cell balancer, so that CP-TR-CC-EC would provide only energy to the pack and EC part of charging would not actually do any balancing.

I would build a cage for LiPOs, which would fit in the battery compartment and provide sufficient airflow for cooling. LiPo batteries can easily provide high currents without to much warming. My new T-Rex 600 flies with discharge between 20-30C and batteries do get warm-hot, but with 40Ah Kokam pack, that 6kWh capacity, the maximum current from the batteries would be 3-4C, which is well within any considerable warming.

When they charge with 1C (for my RC helicoper (6 cell (22.2V nominal), 5Ah) FlightPower batteries), they don't get warmer at all.

The cutoff voltage in the newer software must be higher! Where do you get the 105V number from?

I believe that is an unusually high voltage, and if it is a regular occurrence, will reduce the life expectancy of your pack.

152/102=1.4901V/cell! That is higher than what I get for the final voltage for individual cells on the bench: 1.445V to 1.450V is the end voltage at 3A charging, they heat up to about 40degC in room temperature at that stage! In my expeience the only time you get to 149-153V (temp dependent) is after a deep discharge.

I do not know if this is close enough for the stock BMS.

The EQ charge (new software) could severely overcharge and destroy a Li pack, IF it just continues to charge at 3A for x amount of hours. But I have not seen it in action, and have not seen any detailed reports on it so far. It would be nice if someone with the new software could watch and measure what happens during the equalization charge!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Did you notice that those LiPo batteries are only rated at 800 charge cycles? That's less than half the expected life of Vectrix's NiMH pack, and probalby comes at a higher price.

I'm hoping if all else fails, whoever is supplying the packs for Vectrix will make them available for public purchase, since there would be no conflict of interest at that point. One can only hope! ;-)

800 cycles at 80% DOD (Depth Of Discharge). Lower the depth, higher the cycle number. Also, the 40Ah would give 6kWh of energy. Compared to 3.7kWh that is now and aprox. 40kg battery pack compared to 90kg that is now, equals to much higher range and acceleration.

1. I thought it was 105V. I must have misread that when I read that thread.

2. It depends. When I did 3 BALPORs after the winter, it charged to cut-off. All later charges charge to less than that. It also depends on the outside temperature. For example, last fall it CP charged only up to 148V.

3. That's why I would avoid the new software ;-) It is much more consistent that the latest software. I would also have the number of cells, so it never exceeds 4.2V/cell after all CP-TR-CC-EC part of charges.

Pages