Here is a video to give you an impression of the noise created by my Vectrix.

It's driving past the camera at increasing speeds, coasting (or regen braking) from left to right=downhill and going at a steady speed from right to left=uphill.

First pass from right to left at 30km/h, last one at 55km/h.

I plan to post another video for higher speeds.

Multiple other vehicles volunteered to participate as calibration examples in this video - none of them were harmed.

Details to help you through this most riveting movie experience:

35s : taking off

1:58min: regen-braking-by at 30km/h

2:47min : uphill at 30km/h

3:37 min : regen-braking-by at 35km/h

4:33min : uphill at 35km/h

5:10min : coasting at 40km/h

5:58min: uphill at 40km/h

6:40min: coasting at 45km/h

7:18min: uphill at 45km/h

8:05min: coasting at 50km/h

9:00min: uphill at 50km/h

9:38min: coasting at 55km/h

What do you think causes the noise?

Does your Vectrix sound like that?

Will it scare the Kangaroos away?

Can it be fixed?

Mr.Mik

For the leading-up thread to this one look at:

http://visforvoltage.org/forum/2547-vectrix-reports#new

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Today I sent this reply to a private message (PM) I received a few days ago:

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Here is part two of the noise test video.

Four passes:

Pass 1: 0min 10s: uphill at 95km/h.

Pass 2: 0min44s: Coasting at 100km/h

Pass 3: 1min:37s: Uphill at 100km/h.

Pass 4: 2min16s: Full Regen Braking applied at 100km/h.

I am not sure what causes the noise. Part of it is gear box sound.

I was told it might also be electro magnetic whistle from the eddy currents produced by the VFD (variable frequency drive), especially if it does not get louder with increasing speed.

And it certainly sounds louder at 35km/h than at high speed.

.

The Vectrix brochure states:

http://www.vectrix.com/live/pdf/BROCHUREVECTRIXELECTRIC.pdf

Does that mean my Vectrix has a problem?

Any comments anyone?

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

I suppose you have already done that but does the wheel rotate properly without vibrating when the scooter is on its stand ?

I test rode the Vectrix in Milan and don't remember such variable noise.

Jean-François

Mine does not make that pulsing or intermittent sound. It's much more of a constant whirring. My first guess is that sound does not sound like something good...

Has any Vectrix tech heard it? Did it just start making it?

Thanks for the hint, Jean-Francois. There is no centre stand - and if there was one then the motor would be disabled when it is down. But when I had the bike on the rock for battery conditioning purposes the wheel did not appear to vibrate excessively.

I'll check it more thoroughly one day!

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Hey Mr Mik,

first of all, thanks for all your hard work in seeking - and giving support to all of us EV-ers....please keep it up!

I have seen in disbelief the various answers by Vectrix corp. trying to crucify you for being pro-active...very sad.

I was so darn close to getting the V, but the noise of the goddarn tranny kept me from it, plus I was unsure about their state of debugging. (Glad I waited....!)

The noise your Vectrix displays on the video is highly disconcerting to me. It must have gotten louder, otherwise you would have been aware of it earlier....maybe they have bugs in that department, too.

Very sad, I hope they respond appropriately (they should rent a shack with all parts close to your neck of the woods hahaha...)

The V I personally testdrove was also pretty loud (the whine) but it was even, not "out-of-round-sounding" like yours.

Boy I sure wish they could get their act together. Sorry for your troubles, but keep at it, we are, after all, driving the future!!

Wow Mik,

That is quite the oscilation you have there.

My bike sometimes makes a simliar noise where the frequency is dependent on speed...

But nothing that severe!

On my bike when it does that slight woble it usually goes away soon, if it doesnt or is severe enough I will stop and reboot the bike.

I like to imagine (yes, I imagine a lot of the technical aspects of this vehicle) that the laser/wheel device is out of calibration...

I still havent found what initiates it on my bike, but its NOTHING like that.

Can you feel anything physically in the bike?

just a stray thought, but maybe taping a wireless bluetooth mic in different places would help pinpointing the source of the noise.

Can you ask them to describe what electromagnetic whistle is in more detail?

Reviewing the controller page, it mentions pulse width modulation. Under the Vectrix specs page, the motor is listed as a Brushless DC, radial air-gap motor. These are controlled with pulse width modulation, not a VFD. Though, the switching frequency may still be varied. Eddy currents are produced when a moving or changing magnetic field intersects a conductor.

I suspect a mechanical defect in the gearbox. The noise appears to pulse at the speed of the wheel rotation. The outer planetary gear ring should be fixed to the wheel.

[url=/forum-topic/motorcycles-and-large-scooters/587-my-kz750-electric-motorcycle-project]KZ750 Motorcycle Conversion[/url]

[url=/forum-topic/motorcycles-and-large-scooters/588-fixing-my-chinese-scooter]900 watt scooter[/url]

Pic from http://www.electri

Thank you for your input everybody!

Due to ongoing compter hardware problems I am not managing to edit video and answer posts as well as I would like. I am using an old and very slow computer and have not even seen the Vectrix Noise Test Video myself (I can hear the sound and see a still picture every few seconds).

So please excuse that I cannot answer individual posts thoroughly at this stage, I'll just try to address questions in this one reply.

Here is a Video of the gearbox noise that my first Vectrix made when being pushed back and forth. I had initially put it on Youtube as a private video for Vectrix techs, asking them if it's normal. Apparently it is. Time to make the video public, this whining noise is completely unacceptable and is obviously stopping people from buying a Vectrix.

My first Vectrix made a similar noise to the current one, but not quite as loud.

.

Back to the noise on this second Vectrix:

There noise was there from the beginning, has not clearly changed in any way.

It's annoying, embarrassing (when trying to sneak past traffic jams etc) and almost hurts inside the helmet at 35-40km/h.

.

I jacked my Vectrix onto the rock again today and did a few tests:

Spinning the wheel by hand:

- there is a strong cogwheeling effect; there are 84 distinct, equally spaced positions in which the wheel stops (Determined by marking on the break disk with a marker pen).

- the initial resistance to turning the wheel is quite strong, then it gets easier once it is turning.

- the brakes are running freely.

Spinning the wheel by running the engine:

- the tyre and rim wobbles a millimeter or two or three?(not measured accurately).

- the noise seem to be coming from the hub area.

- the whole swingarm can be felt to be vibrating. The vibration is stronger when the fluctuating noise is louder.

- with a mechanics stethoscope it was possible to clearly hear various noises but I have not figured out a way of recording this, yet.

- the whining noise is also present when the wheel is coasting to a standstill, which I think means it is mechanical. It is also louder during coasting down at the same speed of 30-45km/h as when riding.

- the noise which seems to be causing the vibrations (or vice versa) can be heard with the mechanic stethoscope all the way to the front fork. The whole scooter buzzes wit it!

I would bet firmly on mechanical friction in the planetary gearbox as the primary cause of the noise. It probably hits the resonance frequency of the swingarm at the speeds where it is louder. And the noise level fluctuations (the vibrato effect) I bet is due to the hub not being perfectly round.

I wonder how much range reduction and wear this causes, and if it is going to get better over time as the gears wear down a bit?

So much for now,

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

MiK

Sugguest you contact Vetrix quickly. You obviously have a copy of one of their R&D bikes that must have been sold by mistake. It must have been built to meet the proposed US federal standard talked about in this article:

http://www.foxnews.com/story/0,2933,348370,00.html

Sell it back to them for a premium :)

You have their solution

I wonder how much range reduction and wear this causes, and if it is going to get better over time as the gears wear down a bit?"......

Have you considered the possibility it might actually get LOUDER??

That was one of my main worries.

The tech at the Expo in CA told me as well that the noise was a safety feature (me and my buddy who got the test ride laughed for a good while after that about that ridiculous statement)

Selling this as a safety feature is like saying the Hummer has a built in safety feature, requiring it to return to the gas station every 2 days or so in order to make sure the tire pressure is right....sorta like forcing the owner to go around the vehicle as he refuels....yeah right!!

This is classic think-tank-cubicle-warrior BS !

So sad, the V is the only promising concept out there ;-(

Have they responded to your inquiry about the noise yet, Mr Mik?

Ok, let's believe the noise is a safety feature.

A car reversing makes a very similar noise.

So they may have added a cog in the gearbox to make this noise or build the entire gearbox to be noisy.

In that (any) case the noise is the result of dissipation of mechanical energy therefore electric energy wasted. And also increased wear because what's vibrating wears more than what's not.

Or the "safety feature" is just the result of a last minute "How can we justify the noise?!" brain storming from brilliant marketing team.

And the V is noisy only because of its coggy gearbox which could have been replaced by a nice driving belt much more efficient and silent...

The noise from the motor can be reduced by an appropriate signal command (sinusoidal) and stator/rotor frame design.

In any case, Mik' vibrating noise is not normal. What do Vtechs answer you about it?

Jean-François

Yes, because of straight cut gears on the reverse vs helical cut gears on the forward gears.

The entyre gearbox is apparently straight cut.

I think you are right there, but I am not sure how significant the energy loss into sound pressure is. Leaving the head light permanently on is insignificant in regards to range.

That might be the case. I also found information that straight cut gear boxes are used in racing cars because they are much tougher. Vectrix claim they expect the gearbox to be maintenance free for the life of the scooter, so noisy straight cut planetary gears might be the price for reliability...

That would need replacement at some stage, though.

I really doubt that a significant part of the noise of my Vectrix is caused by electrical phenomena. I believe the swing arm resonance frequency has something to do with it - it might be acting as a resonator at 35km/h.

It's hard to be sure from the video, louder than most Vectrixes, not the loudest ever heard though.

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Ok, i wasn't aware of the effects of the gear cut.

I wouldn't be disturbed by a belt maintenance if it improves noise, but it's personal.

I learned about motor noise in a thesis about BLDC motor conception.

I've asked if it is available in english but if you read french, i can put a link here.

The problem with your noise is not so the intensity but more the up and down variations.

Jean-François

I noticed that occasionally there is a sort of "Grunt" noise at low speed and then tried out if this is repeatable by going slow.

It is!

When riding at a steady 8km/h, there is a loud grunt accompanied by vibration with (almost) each revolution of the wheel.

This does not often become obvious, because the rapid acceleration through this speed band usually only allows for a maximum of one "grunt" to occur.

This definitely makes it clear that the noise of my Vectrix is caused by mechanical problems rather than electrical phenomena in the motor.

The "Grunt" happens at 8km/h and is synchronous with wheel rotations.

It causes vibrations so strong that I can feel them through the seat!

I viewed some of the videos I took earlier (when my first Vecrix was replaced under warranty because of a blown main fuse) and noticed that the same sound was present on day one; I did not notice it back then because I was too busy pushing my Vectrix up the driveway.

The range was so poor that I was not really interested in much else.

(See: http://visforvoltage.org/forum/2707-how-best-break-vectrix-anyone039s-guess#comment-14852 for details).

.

The YouTube video below is a compilation of photos and video taken during the first "deep discharge" ride of my replacement Vectrix.

The photos were taken just before or after the video snippets, I put them in because it makes it possible to see the display clearer and they are date-stamped.

During the initial acceleration in the video the fluctuating whining sound can be heard clearly, the same sound as in the video I posted at the beginning of this thread.

During the slow pushing uphill parts later in the video you can clearly hear a "Uh-waaaah-Uh-waaaah-Uh-waaaah" sound, at least if you use headphones.

The "Uh" sound is accompanied by the vibrations.

The (involuntary) crawling speeds towards the end of the first few rides on the replacement Vectrix clearly show that the problem was present on day 1.

Thus the trouble from back then turned into the diagnostic tool of today....

Because I usually do not ride that slow I did not notice the vibrations much once the battery was broken in. But it is of course the same vibration that causes the higher pitched fluctuating sound at higher speeds....

.

.

I managed to record this next video recently by holding a camera in my hand whilst driving uphill at 8km/h:

I marked the tire to make it possible to see if the noise always happens at the same point during the rotation of the wheel, and it does.

.

A previous attempt by taping a camera to the side of the Vectrix was unsuccessful because the vibrations are so strong that they cause the camera to record an artifact sound that is completely different from what I hear when riding my Vectrix.

Here is the view from that camera:

And the recording with the artifact due to the vibrations:

It does NOT sound like that, it's just to illustrate how strong the vibrations are.

.

.

Because of the severity of these vibrations and because I received advice from Vectrix that it would be prudent to check the gearbox oil level, and that I should also please check that the wheels spin freely, that the brakes are not binding, I decided to have a competent person open up the gearbox - and of course I took photos:

The oil levels looked OK, there should be enough to keep it all lubricated when the Vectrix is upright again...

I hope no-one interprets this as a Warranty Condition Violation.

I have repeatedly pointed out the noise problem to Vectrix, both verbally and in emails. Due to the distance problem and their obvious time pressures/constraints and inability to give me a clear date for when they will come to check the Vectrix and to rework the battery pack and install the new side stand, I feel it would have been irresponsible and potentially dangerous not to check that the gear box is lubricated properly.

A scooter with a gearbox this noisy should not have been delivered to a customer in the first place; it should in fact not have passed the quality control in the factory!

I am forced to have this work done by non-Vectrix people due to the totality of circumstances.

I have hours of video footage showing that this noise problem existed since delivery.

And the glossy brochure delivered together with my first Vectrix claims:

"Noise levels: Negligible".

So I hope they think twice before trying to give me any grief for getting their job done for them, for free!

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Here is how the gearbox noise and vibration of my Vectrix was reduced significantly:

Once the gearbox was open it was very clear that there was a lot of mechanical friction noise emanating from the gears when the wheel was spun by hand.

Therefore the decision was made to not just close up again, but to investigate further.

The use of precision calipers revealed that the gears are rough cut, with differences between the individual teeth on the gears too large to enable detection of differences between the 3 planetary gears.

It was also not possible to detect or rule out an "off center" position or oval shape of the ring-gear.

Because the tire gets in the way of the calipers, the wheel had to be removed; the oil cover was replaced first to prevent any dirt from entering during this procedure.

Further dismantling of the gear system was necessary to detect the cause of the noise and vibration.

The metal part holding in the three planetary gears makes it impossible to measure across the center of the achsle and was removed.

Sun gear: 23

Planetary gears: 41

Ring gear: 106

Because measurements alone could not determine what exactly caused the vibration in the gear system, the planetary gears were removed.

It was at this stage that I had the idea that led to the breakthrough:

The planetary gears were replaced one at a time to determine if they behave any different to each other.

This makes it possible to clearly hear and feel what the individual gear is doing.

With each planetary gear in its original position (by itself) the wheel was spun by hand (see below for technique) and the noise and vibration evaluated.

This revealed that planetary gear 1 (PG 1) caused a lot of noise and vibration, PG 2 almost none and PG 3 a little bit.

Next step: each PG was tested in all positions to determine if the PG or the position causes the different behavior.

The result:

PG 1 is noisy in every possible position.

PG 2 is quiet in every possible position.

PG 3 is a little noisy in every possible position.

Next step:

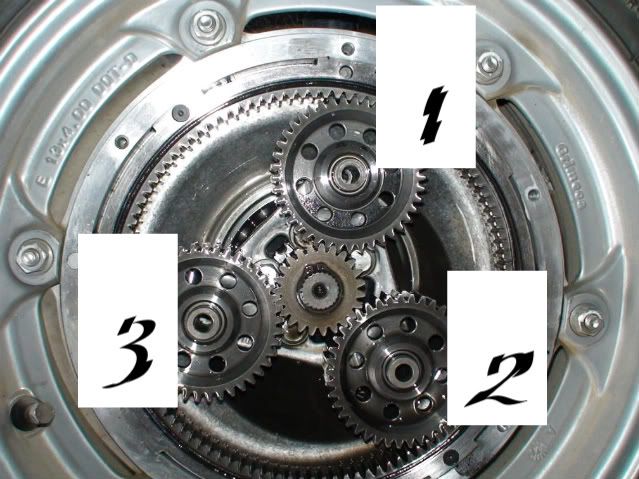

Find the least noisy position for PG 1; this turned out to be where PG 2 used to be.

Then find the least noisy position for PG 3 but only between position 1 and 3; this turned out to be position 1.

PG 2 was assigned the remaining position 3 because it was running smoothly in any position, anyway!

It is important to do this with only one PG in the gearbox at a time, otherwise the noise from the two other PGs will make it hard to hear the differences.

The overall result was a clearly less noisy gearbox when spun by hand.

The gearbox can be rotated by screwing one wheel nut back on loosely, placing a socket and attachment onto it and using this to easily and smoothly turn the gearbox.

.

Original positions:

Best positions:

.

.

.

.

Putting it back together is a reversal of the dismantling procedure.

(Who would have thought that!)

Precision torque wrenches with appropriate settings were used throughout the re-assembly.

.

.

Some of the screws also need to have a thread-locking product applied, and some need a paste that prevents corrosion and permanent locking of the nut or screw.

.

.

I have much more documentation to prove that the job was done competently and without doing damage to the Vectrix.

And coming up is the the video that shows the improvement to the vibration at 8km/h...

This modification works!

..

..

..

This post should be seen as what it is:

An attempt to help fix one of the main problems of the current Vectrix model.

The noise levels of some Vectrix scooters are much higher than others, and my replacement Vectrix is one of the noisy ones.

Many people have been put off by the noise, and some have commented on V that the noise had stopped them from buying a Vectrix.

It is a serious problem, and here is the solution:

If I had three planetary gears exactly like my PG 2, the gearbox of my Vectrix would be very quiet.

Even just putting each of the three PGs into their optimal position has had a significant impact.

There are 48 possible ways to put the three planetary gears into a Vectrix - only a minority will have them in the optimal position due to chance.

Many Vectrixes could have their noise levels reduced with 2 hours of labor without additional parts using the above procedure.

A proper fix would involve more precise machining of the gears, or better quality control to stop the few bikes with the extreme noise levels from leaving the factory.

.

.

I believe that the noise would also slowly get better over the course of several 10000kms, because the offending PG will wear down a bit and fit better.

Both the Sun gear and the planetary gears have a prime number of teeth - I believe this means that the effect of a slightly larger PG would be spread around evenly on both sun- and ring-gear until the PG has worn down.

But this is just me practicing my diving skills again whilst out of my depth....coming up for air soon!

.

.

I had considerable help from people with some experience with planetary- and other gear systems. Thank you girls and guys, you know who you are!

.

I hope this preliminary work will help the Vectrix tech to improve the noise and vibration problem of my Vectrix further when he visits in a few days.

At 35km/h the noise is still unacceptably loud, thats where the noise peaks; but it is much improved at lower and higher speeds.

Here is the 8km/h video after the optimisation procedure:

.

And here the "before" video again to make comparison easier for you:

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Have advised Vectrix Australia of the previous post, awaiting a reply....

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Continues at: http://visforvoltage.org/forum/3462-vectrix-warranty-voided

This information may be used entirely at your own risk.

There is always a way if there is no other way!