Can halogen heaters designed for use with 220-240VAC be used as a load to test DC batteries?

Does it need a minimum voltage to function, or is it "dimmable" like incandescent lights?

Here is a page with a bunch of similar products: http://www.amazon.co.uk/b?ie=UTF8&node=3147691

I hope it is possible to use one of them for testing 125V DC and 150V DC batteries; and to use two of them in series to test 300V DC batteries.

The halogen heaters I have have three elements with 400W each, so it might allow a degree of "fine-tuning" the current draw.

This is of course quite dangerous - fire and electrocution are very real risks here! Do not try any of this unless you have the right equipment and the know-how!

We should think about a handbook section on battery load testing. Anyway it depends on whether it must be AC but I'd expect a heating element wouldn't care between AC and DC.

One of the load testers I have is meant for 12v car batteries and it's simply a heating element.

Richard Hatfield has in his garage an interesting contraption for load testing. FWIW for ad-hoc load testing it's enough to have a fixed resistor-like widget to dump current into. But for more official load testing the resistance of the load has to vary over time because an official load test keeps the current rate the same throughout the test. The gizmo in Richard's garage is a long tube that can run a cooling fluid through it, one lead is connected at the bottom of the tube, and the other connected to this roller gizmo that can roll up and down the tube easily. The resistance of the load depends on how far down the roller gizmo is located at any moment, which lets you adjust it during a load test to keep the amp rate constant.

FWIW I have seen pictures of portable AC heaters used as load tests of DC batteries.

- David Herron, The Long Tail Pipe, davidherron.com, 7gen.com, What is Reiki

Mik

I have been using every thing under the sun for load testers. It makes good sense to use 200 to 240 volt resistive and Halogen heaters as load testers. They last for ever and ever on batteries. For 12 volt I use Harbor Freight 50 and 100 amp load testers and for really heavy loads I use an Inverter hooked up to a 1200 Watt heater. Reason there is most inverters turn off at 10. to 10.5 volts and can't ruin a 12 volt battery. For my VX-1 is use and Anderson SB-50 and it serves to measure pack voltage and run my tools. I have an SB-50 to NEMA 5-20 adapter cable. BTW I even mow the lawn with 125 volt DC. Even PTC heater work on DC also. They are those EV heater made from bathroom heater cores. In my house I use 240 volt resistive heaters on 120 volt to give me 1/4 power / heat. A 240 volt 2400 /2500 watt heater makes 600 watts of heat on 120 volt. Half the voltage and half the current = 1/4 the power.

It makes perfect sense to use a Halogen heater as load. Best load test around too.

Rus

KB1UKU

It does indeed work a treat!

But a word of caution: The switches on such devices designed for AC use cannot disconnect the DC current.

The switches fry the moment you try to turn the load off! And that will be a problem with most switches.

I use a SMR (System Main Relay) from a NHW10 Prius battery and switch the load on and off by controlling the 12V supply to the SMR. That way it can also be timed.

The issue with the halogen heaters it that they also have a switch which is designed to turn them off in case they tip over. Move them a little bit while turned on, and they start to send smoke signals! I removed both these switches.

The switches seem to cope fine with turning the load on.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

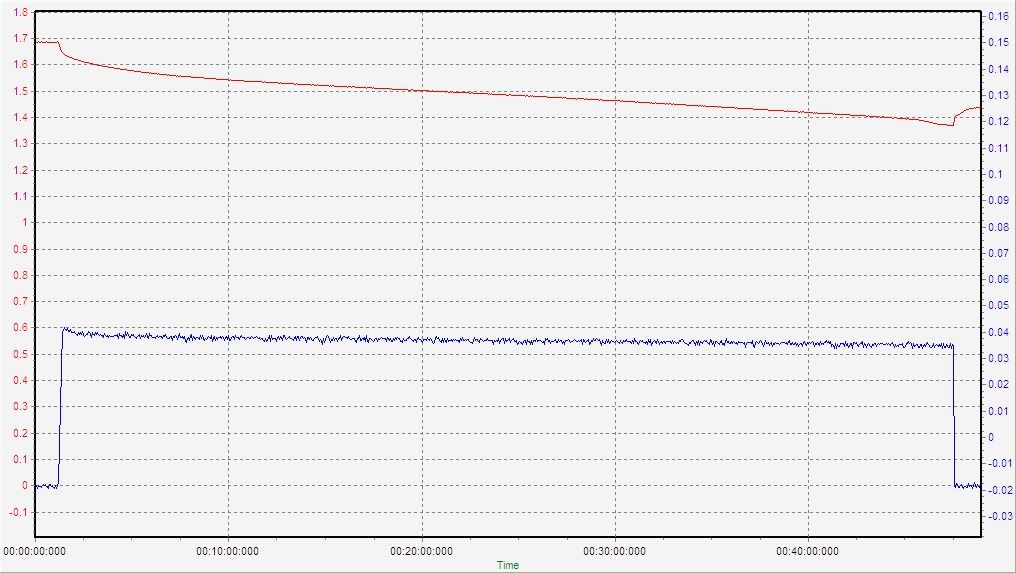

Here is what it looks like: Detecting "Empty" as defined by a single cell in a 120s NiMH battery (Prius NHW10) under 6A load dropping to zero Volt:

Both graphs to be read on the left (red) scale:

Red = Volt x 100

Blue = Amp x 10

(The battery has actually higher capacity than this test shows, because I have run several short tests during the testing / setting up of the whole load tester cable mess! All up probably another 15min at around 6A.)

.

.

Now this battery is charging again. I'll repeat this 5 times or so to ensure that I'm not throwing out good cells that just needed to be cycled to access their capacity again.

.

Later on, this same setup will serve to do "5 deep discharges" on the Vectux battery without risk of getting run over or not making it up the driveway!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Mik

I should of said something like that about switching. I thought you were just going to use an Alligator clip and load test for a few seconds or a minute. I use an SW-80 contactor for magnetic blow outs to turn on and off load for my heater in my truck. Power for SW-80 is a DC-DC converter inside to power coils. For my larger load tester I use a reversing switch wired in series to give more distance inside contacts. Using a 10 Amp load sure doesn't take long to find bad cells. In USA the standard joltage is 100 to 125 volt stuff and most AC type switches weld almost instantly. But local electrical supply houses here like Standard Electric order me 250 volt switches that even are rated for DC. If you do use alligator clips to load test, then do connections fast or it can draw an arc very fast. For some reason Halogen heater make a faster arc than Ni-Chrome wires in heaters and both are great for load testers. I think because of filament type glow making faster heat.

Also same thing using fuses too. Those puppies got to be rated for DC. Use ANN-50 for fuses for Bussman has a lot of DC rated fuses. Semiconductor fuses are good too for DC.

I use a lot of tools on DC and all of our vacuums are welded switches because I keep forgetting to unplug vs switch it off.Some of the tools I use are Craftsman 3.0 HP table saw, Skill Saw, Jig saw, router, air compressor, and all of my drills work fine on DC. I mean great really. I even read the label on some tools and it says AC or DC.

KB1UKU

Good idea!

For now, I'll just add to this post my experiences of what can be done with these AU$19.95 halogen heaters of 400W+400W+400W.

Here is the second discharge of a NHW10 half-pack (HP), which means 120s NiMH with about 6Ah capacity.

This time it is all in one graph, because it's all set up and working.

About 4.21Ah were drained until the first cell dropped to zero volt; it was the same one as the first time, no surprise there.

Discharge 3 will hopefully answer the question if the capacity of this cell is increasing as a result of the deep cycling.

The sharp drop of the single cell dropping to 0 volt is now at the very end of the graph - I had the DMM attached to the "Stick" (module) with the cell in it to allow immediate verification of the voltage drop, saving the 2 minutes it takes to measure all 20 sticks whilst voice recording the results.

.

While I am typing this, the two halogen heaters are working in series to discharge a complete NHW10 battery, 240s NiMH, at 3.8A. It started at 320V and it will be a bit harder to see the 1V drop. Just a few minutes to go now.....and it's nice and warm in the garage! Not a good method for summer battery testing, though!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Here are the results of the 240s NiMH battery test:

I have not made my mind up, yet, if this is a good or a bad result!

Either this is a battery without a significantly under-performning cell (good), or my setup is not capable of detecting single empty cells in such long strings (bad).

Anyway, these batteries are becoming a threat of ruining my life! So I shall change my approach to a less kind testing regime and ruin them, instead!

The NiMH batteries have shown to be so resilient to heavy abuse that it might well be more efficient to use testing methods that destroy marginal cells quickly, so that they become easily identifiable.

Stepped discharges might be the way to go, as in:

"If there is a cell that cannot even produce 2Ah on first discharge, it might as well be distroyed."

"If there is a cell that cannot produce 3Ah on second discharge, it may as well....etc etc etc until there are either clearly identified bad cells, or the pack is identified as good and has had multiple (progressive) deep discharges to access the full capacity.

For some NiMH cells, like these Panasonic cells from Prius (?and Honda Civic), this should probably also be combined with quite aggressive over-charging and heating of the cells, to rejuvenate them!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

How good is this!

Results of the third DC on the NHW10-02 HP1:

Compare this to the results of the second DC:

.

In both tests it was the same stick (module) S18 which was suddenly dropping by 1V, but in the 3rd DC it happened much later, at a time when the overall string voltage was falling already.

(46.5min/60) x 5.5A = 4.26Ah in DC 2;

(59min/60) x 5.5A = 5.4Ah for DC 3. A 27% improvement!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

I received a question about the quoted post below:

Mik

What is that glitch at exactly one hour? Did a cell open for a millisecond? Is that a strip voltage recorder?

Here is some more explanations:

The staggered start is because I switched on one 400W element at a time when the test starts. Makes 4 steps.

The jump in current at around 40min occurred because I added in 2 incandescent globes of 150W (@240VAC) each.

The brief drop of current to zero at 1hr and 1hr 13min is due to the timer turning off the relay which turns off the load. I try to always set the timer for shorter than what I think the battery can take, so that nothing goes wrong in case I get distracted.

At the end, the timer again turned it all off. I can of course terminate it all manually at any time, too.

The recording is made with a PoScope - a digital oscilloscope with a bunch of additional functions. The current is measured as a voltage across a 10mOhm shunt in series with the battery.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Here are the results for DC Nr 4 for the NHW10-02 HP1:

The weak stick S18 has completely blended in with the rest of the half-pack!

Capacity seems to be up by another 5% or so.

This discharge was done when the battery was 52degC hot from the last charge, it increased to 54degC during the discharge. That is bound to have some sort of effect on it all, but I don't know what exactly.

I think I'll let the battery rest and cool before charging and do one more exercise cycle at 32degC, fresh off a 0.15A trickle charge.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Here is the second discharge of the entire 240s NHW10-03 battery, same as the last one shown.

As during the first discharge, I cannot spot any prematurely empty cells in the discharge curve, but the whole battery might be in good nick! When the battery is still in one piece, like this one, individual stick voltage measurements are not possible (unlike when testing half-packs on the bench).

I increased the discharge current (at start) to 6A by adding in four incandescent heat lamps (rated as 275W @ 240VAC each) to the two halogen heaters. Now it really gets toasty warm in the garage!

.

This is of course quite dangerous - fire and electrocution are very real risks here! Do not try any of this unless you have the right equipment and the know-how!

.

.

This information may be used entirely at your own risk.

There is always a way if there is no other way!