JDH: CB750 Conversion - Let the Fun Begin!

I got my batteries delivered on Friday. I now have about 360lbs of lead to play with! Along with a whole bunch of other stuff and I need to fit it all in that poor, unsuspecting 750 frame...

I went to the local metal supply shop and bought some 1/8" strap and some L shaped as well. I've been playing around with specific mounting strategies in my mind for a while - now it was time to try them out for real. So far, touch wood, I've been reasonably happy with my progress.

The front four batteries are now in place. The lower three are held together by 4 L-shaped corners fastened together with 5/8" threaded rod. Four flat straps are used to provide top and bottom support and to form the third and fourth side of the box. The middle bottom battery rests on two brackets (made from the strap) which attach to pre-existing motor mounts. The fourth battery sits on top of the middle battery forming an inverted T. I'm reasonably happy with how it has turned out so far. I need to fasten the bottom middle battery to stop side to side and back to front movement - I plan on using more brackets made from flat strap and attached to the engine mounts and four more threaded rods. The additional straps will fasten to the frame and spread the load from the existing two straps (four bolts). The additional rods will be longer and will also fix the top battery in place.

The battery on top will also attach to the frame - different frame attaching point than the bottom battery - not sure on this yet. I'm holding off on mounting this top battery and the fifth battery (which sits over the top of the motor) until I've fitted the motor. I'm in process of ordering an ADC motor 6.75 inch diameter, 11.3 inch body length (not including shaft). It's rated at 8hp continuous, 35hp peak. It's a base mount motor and I'm hoping that I can simply attach a floor between the two frame rails and mount the motor to that. Not sure if I'll get the floor welded in place or whether I will drill into the frame and bolt the floor in place (Bidwell's El-Ninja uses lots of bolts in the frame). If I do go the drill and bolt route then I'm starting to think I might be able to complete this without welding (that was the original goal after reading Bidwell's book - but then I started to doubt the feasibility of this approach.)

Here's pics of what I've done so far. Bear in mind that nothing is finished or tightened down - it's still very much in the design stage. I sure wish I had access to a full metalwork shop and that I had the skills to fabricate better brackets - but seeing as so far I've used nothing more than a drill and a hand held grinder I'm pretty pleased with myself! (I run the risk of "pride before the fall"...)

OK, so it is kind of wide! Maybe I should have one of those "Wide Load" signs? I could have made it a little narrower (maybe 26 or 27 inches rather than 28). The original motor was about 23 inches at it's widest point but the bulk of it (the cylinder block) was probably more like 18 inches wide. Ah, whatever, at least the weight is low. This represents a little less than half the major weight addition - I have another 3 batteries to add and the motor (which is 60lbs of fun).

Hmmm, at the moment I'm actually starting to think I might be riding this in the spring... (this is by far the most ambitious mechanical project I have undertaken so I've approached it with a healthy dose of skepticism!).

- jdh2550_1's blog

- Log in or register to post comments

Who's online

There are currently 0 users online.

Who's new

- eric01

- Norberto

- sarim

- Edd

- OlaOst

Comments

Re: JDH: CB750 Conversion - Let the Fun Begin!

With the battery tray that wide, will it be scraping the ground when you go into turns?

- David Herron, The Long Tail Pipe, davidherron.com, 7gen.com, What is Reiki

Re: JDH: CB750 Conversion - Let the Fun Begin!

I don't think so - this is going to be more of a stately cruiser than a screamer. Think slow easy turns rather than knee sliding, sparks flying. :-)

There's a fair amount of ground clearance - when I get the bike fully loaded I'll measure the ground clearance and then I should be able to figure out my max lean angle.

If it's a problem then perhaps I'll mount little caster wheels... ;- (Or, more sensibly, remount the batteries higher up)

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Yeah, I'm thinking the same thing John. If it were me I'd think about shortening that seat and maybe puting a box behind it like the scooter folks sometimes do...for a battery back there. Or, I think "saddlebags" and I think why not have a couple of battery boxes made to fit the sides of the rear bolted on and down each side like saddlebags? I know you don't want to get into welding, etc. but since you're spending a fair amount of bucks here anyway...I'd make the battery placement a priority and put my money as well there. Otherwise I'm afraid that you'll end up with something impractical to ride. I'd also look into building or having built some fiberglass boxes...for weight limitation. Also, what about moving that tank and re-positioning the frame bars there so at least one battery can sit in that space perhaps covered by just the top half of the tank enclosure...insulated from the battery of course. Also, what about turning those batts up on end in some cases...as I understand you can do that with sealed batteries? Might save some space. And, there's no rule that says the batteries can't be placed laterally along each side of the frame all the way down to the rear. I know the motor has to go in there somehwere but seems to me that might be workable....figure out how to use the space along the length rather than creating this perhaps unacceptable width. You may also be creating a side to side center of gravity which will be a problem in keeping balance easily.

Not knocking your work here John...just trying to provide some constructive comments!

Gushar

Gus

Re: JDH: CB750 Conversion - Let the Fun Begin!

Thanks for the input - I do appreciate it. However, a couple of points to bear in mind:

1) this is only 4 out of the 7 batteries. Batteries 6 & 7 are going in the "saddlebags".

2) this is a first attempt at the simplest mounting arrangement - if I find it's not suitable I'll change. Simplest first change will be to raise all batteries in the inverted T up by a couple of inches. Next, will be to raise the outside two batteries up further still. These four batteries weigh about 220lbs in total - which is similar in weight to the engine that's being removed - I'm not sure of the weight distribution of an engine but it certainly carries a fair amount of weight higher up and towards the front - in the cylinder block.

3) my goal is for little or no frame modification and little or no welding. If I can reach the finish line with no welding and no frame mods then it becomes much easier for folks to repeat for themselves (if they want to)

4) the width "looks" bad - but I'm not ready to concede it's a problem yet. Have you ever seen a Harley with those wide running boards? Also, this is only about 5 inches wider (2.5 inches per side) than the original bike. I also need to find some data on what is considered a reasonable max lean angle and see what my max theoretical angle is.

5) I do expect this to be "close" to the widest possible and still achieve good lean. Therefore, I might have to put some form of extension or guide in place to alert the "enthusiastic rider" that they're approach the limit (worst possible situation is the user leveraging the rear wheel off the ground!). I should make the guide out of something that will shower a lot of sparks - that should get the rider's attention.

6) At the end of the day if I can't package these batteries - I can down size to 55Ah.

Please keep the comments and constructive suggestions coming - I'll keep you posted on what transpires...

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

John you've probably already been looking at this and made the decision on total voltage with this consideration...but you know it seems to me that you reach a point with these type batteries because of weight that you loose all or much of the increased power with higher total voltage because of the weight of the batteries to power that size motor/system. Might you rethink that and make sure that you can't go down in voltage...say from your (if I'm correct) 84 volt string to something like 60 volts or max 72? I mean with one or two more batts to get to 84 volts are you gonna get that much more bang in power? I guess it also depends upon what you're looking for in speed, range, etc. I would as well look at some things like the weight of wheels, etc. and see if you might trim off a few pounds there by replacing the stock wheels (not tires) with lighter ones....and anything like that which might lighten the total weight and maybe somewhat lessen the power requirements. I just believe I'd settle for lower speed and less batteries (total voltage)...or perhaps find a really good motor that would give me the best power at a lower total voltage. Anything to lessen the number of batteries. I mean you really are limited by the number of batteries (especially SLA) you can reasonably carry on a frame of that size.

I guess it all depends too on what you're looking for. As for me I'd rather have a practical and reasonable looking machine with less power and a shorter range than a more powerful one, greater range that looks really odd and takes every second of your attention just to keep it balanced as your going down the road.

Gushar

Gus

Re: JDH: CB750 Conversion - Let the Fun Begin!

I haven't finished it yet! It will look better when it's done (maybe). ;-) Also, I'm not too worried if it looks a little strange (although I take issue with "really odd" - how dare you! (just joking))

I've ridden motorcycles for long enough that I just don't think this will be a problem. Weight distribution is down low. Furthermore some of the weight will be directly over the rear wheel - so it will be more like riding the bike with a passenger on the back. I think you're putting too much emphasis on those outrigger batteries ;-)

Of course if I'm wrong then it's back to the drawing board - nothing is set in stone and things can be changed around.

My first intent was 72V and a Perm motor. Then Andrew turned me on to the ADC - and I decided to climb higher up the voltage chain - in part to compensate for it's greater weight and slightly lower power output. I was actually hoping for 96V - but there's a big step up in the price of the controller (from around $400-500 to around $1200-2000). So I nixed that. The range of 50 miles is a somewhat psychological goal - it just feels better to be able to say it has a 50 mile range.

More weight certainly affects top speed - but not all that much. It does kill acceleration though! The one thing that I've not really been able to get a good handle on with my math is what acceleration to expect. For this project I just want "good enough" not "great". I'm choosing range over acceleration.

Now, you should have seen it when I mocked up six 110Ah batteries - that one really was a monstrosity!! :-)

BTW, the gas tank is already just the top half - I hope to put the seven battery chargers up there. The controller and two DC/DC converters are going in the old oil tank/battery space. I should probably put in a bracket for the kitchen sink - coz I'll likely add that too at some point!

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

So If I'm getting this right then you plan

4 Batteries in the front section

1 Battery over the motor

2 Batteries as saddlebags

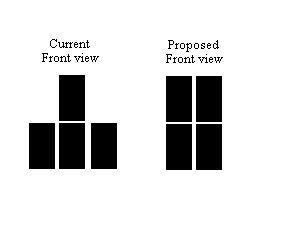

If that is the case then why not have the 4 batteries that are up front in a square? See pic.

This will take care of the width problem and make a nice neat looking package.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Yes you're getting it right. However, the design you suggest won't fit between the frame rails. In the inverted T the two center batteries are inside the frame rails. The bottom two batteries are outside the frame rails.

Thanks for taking the time out to post your idea though.

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Looking good John.

I took my project for a ride last night. (Back and forth in the length of the garage. (We were getting pounded by the snow storm last night.)

Everything is woking well. I was dissapointed, as the motor does not seem to be making any torque. I am hoping to be able to play with the programing tonight and make some improvements. I don't know any of the controller settings sent from the factory, as I have not hooked it to the computer since it arrived.

Hopefully I can change some parameters to increase motor torque.

I'll post some pics soon.

Mike K.

Racermike

5 years ago I met Jesus and he total ruined my life. I have never been happier.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Hi Mike,

You're much further along than me! I just ordered my motor and all the other sundry bits from EV America.

I pretty much have everything now.

Still to order:

1) A circuit breaker. I'm going to have a circuit breaker that's attached to the old clutch cable (idea stolen from Andrew).

2) A selection of front sprockets. I'm hoping for a 9 tooth sprocket on the front - I can't remember the specs off the top of my head. Depending on what's available I'll get an 8, 9 & 10 tooth to experiment with - however, I kind of doubt they go down as small as 8 teeth.

3) A new chain.

4) Several "round tuits" because I've got a lot of work to do!

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Hey John.

My conversion was pretty simple in comparison. It was amazing how well the Kawasaki 110 4- wheeler accomodated the conversion. The frame was perfect for mounting the batteries and the motor.

FYI I was stressing over finding a sprocket for my motor. A friend of mine told me the #40 chain was compatible with the #428 chain. I was able to order the correct sprocket from McMaster-Carr ready to use for $13.20.

A little research revealed the #50 Chain will work on the #520 chain.

The smallest sprocket I could find in either chain (from McMaster-Carr) was a 9 tooth with limited bore sizes available. As soon as you get to 10 or 11 teeth, the available bore size jumps up to 1" dia shaft. The price was about $12. My stuff was delivered next day regular ground UPS.

I didn't know if you knew that already. But I went from being a couple of weeks to 2 days in solving the sprocket issue.

Mike K.

Racermike

5 years ago I met Jesus and he total ruined my life. I have never been happier.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Thanks Mike - I'll check them out. Let me know if you fix your Torque problem.

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

well I rode the 4 wheeler up the street and back yesterday. It wants to go 30+ MPH. I think the "no torque" problem is a function of the gearing, and small battery pack. I think if I had a large enough AH battery pack, it would go about 45 MPH. The speed just keeps climbing untill the battery pack drains. I tried some changes in the controller programing, but I did not realize much change. My plan now is to add a jack shaft to change the gearing. A quick list of parts required to add the jack shaft is about $110. I am also going to experiment with bigger AH batteries. I have the room, I just need to see if I can find some at a reasonable price. The jack shaft will provide many options as far as gearing, and for about $15 bucks, and a master link or two, I can change the gearing in about 15 minutes. Over all, I like the set up. I went up the street yesterday, and it was whisper quiet except for the tires humming. A car went buy in the other direction, and they were staring because "there is no motor". All as you can see is the square battery pack where the motor used to be. When I came driveway and jumped off a snow bank. It was a short ride, but it was fun and inspiring.

Racermike

5 years ago I met Jesus and he total ruined my life. I have never been happier.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Hey John. I meant to comment on your battery placement. The front veiw reminds me of a BMW with the cylinders hanging out. As odd as it may look, the protrutions have been proven to be ok for years by BMW. The low CG will be helpful as well.

Mike K.

Racermike

5 years ago I met Jesus and he total ruined my life. I have never been happier.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Congrats on your first ride!

Yeah, the classic Boxer look - perhaps I'll paint some BMW logos on the batteries? ;-)

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Hey John

I was able to complete the installation of the jack shaft and the new gearing today. We rode it up and down the street a few times. What a nice package this is turning out to be. We found a bad battery in the string, and I think that was causing the "no torque" problem. I pulled out the battery and hooked up the pack so it is now 36V. Without the bad battery, it has more power and acceleration than the 48V with the bad cell. Very encouraging! I am looking forward to a healthy 48V ride!

Racermike

5 years ago I met Jesus and he total ruined my life. I have never been happier.

Re: JDH: CB750 Conversion - Let the Fun Begin!

Looking good!

Some questions:

- How did you mount your motor?

- Does your wiring include a main contactor? I'm confused when I look at the Kelly wiring diagram (a) it shows reverse and I don't want reverse (did you wire up reverse?) & (b) it lists the main contactor twice in different places. What am I missing?

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

John, the way I read the kelly controls diagram.. reverse is just a switch you connect to that spade connector marked REV. It's extremely simpler than reverse on other controllers which rely on different external switches or reversing contactor to reverse connections to the motor. You can simply ignore stuff you don't need - such as the reverse mode, since that's rather unnecessary for a motorcycle.

- David Herron, The Long Tail Pipe, davidherron.com, 7gen.com, What is Reiki

Re: JDH: CB750 Conversion - Let the Fun Begin!

David,

Yes, I noticed that the reverse is easier - although you do still need to wire the motor connections differently if you want reverse (at least for a series motor you do). Are you using a PM or a series motor?

Did you notice that they have "main contactor" listed twice? How did you wire that up? I'm thinking they might just have split the low voltage and high voltage parts to seperate them and make an "easier diagram".

Thanks,

John H.

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.

Re: JDH: CB750 Conversion - Let the Fun Begin!

I haven't done anything approaching a final wiring - what I set up the other day was a quick test that skipped over a few of the safety steps, like there are no fuses, no precharge resistor (because there's no contactor), etc. I don't remember the wiring diagram right now and I'm 2,500 miles from home so it'll have to wait a couple days.

- David Herron, The Long Tail Pipe, davidherron.com, 7gen.com, What is Reiki

Re: JDH: CB750 Conversion - Let the Fun Begin!

Hey Guys.

Looks like you answered the reverse question amongst yourselves. I did hook up reverse (just a simple switch) as it comes in handy with a 4-wheeler. I also like the 1/2 speed option in reverse.

I mounted the motor the same way it was mounted in the Elec-Trak. It sits in a "V" cradle, and is through bolted to the motor housing.

I added (4) 12V-24AH batteries today, and changed the gearing. I love this thing! I can't wait to let others ride it.!

I was just sitting here thinking, and I may try to use reverse as a second speed in forward, to slow the thing down while in the woods, or towing a trailer around the yard. If I swap the motor leads, I can give it a try. It could be a two speed controller type thing. If I am thinking correctly, I may even be able to do it with switching and contactor.

The pictures are of the latest gearing nad battery set up.

Hey John, the gearing hub and sprocket came from Tractor supply. Another good place to go "to engineer on thy fly"

Racermike

5 years ago I met Jesus and he total ruined my life. I have never been happier.

Re: JDH: CB750 Conversion - Let the Fun Begin!

fOR THE LOVE OF GOD! why on earth did you destroy a perfect cb 750? for this experiment? why not a peice of crap suzuki or a yamaha? DUDE!

Re: JDH: CB750 Conversion - Let the Fun Begin!

Why? It's simple. I did it just to annoy you... ;)

BTW, it's on hold while I play my part in bringing the rEV 1 to market - when I have time to start on this again I'm going to use LFPs.

John H. Founder of Current Motor Company - opinions on this site belong to me; not to my employer

Remember: " 'lectric for local. diesel for distance" - JTH, Amp Bros || "No Gas.