I hope to be able to improve the Vectux BMS by re-arranging the cells so that the effect of low capacity cells is more obvious to the BMS.

The 102 NiMH cells are arranged in series, with two Voltage probes taking measurements between cells 27 / 28 and 75 / 76.

There is no way (that I can see) in which the stock BMS can actually shuttle current between cells.

It only uses the measured voltages to determine if there is an imbalance, in which case it might limit power delivery during riding or change to trickle charging during charging.

If low capacity cells are distributed in equal proportions through the measured sub-sets of the whole string, then the BMS will not notice an imbalance even when some cells are unable to accept further charge or are being reverse charged.

But, and that's where my idea comes in, if all the low capacity cells were in one of the measured sub-sets, then there would be a clear voltage difference once these cells are approaching full, or empty, compared to the other sub-sets.

If this works, then it would be similar to the gear box modification which reduces the running noise for next to no costs.

But there might be unexpected effects, or the performance might be reduced so much that it is impracticable.

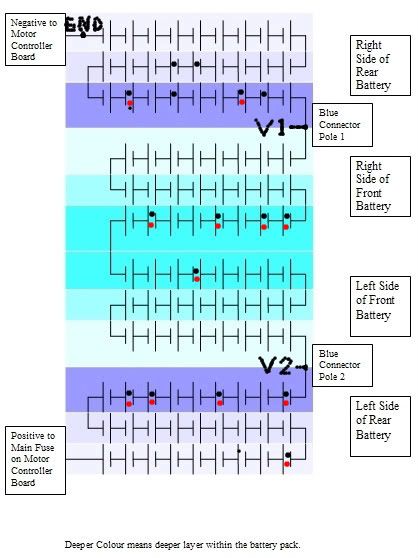

The schematic below shows the 102 cells (in their 12 modules, in two batteries, with a 2-pole connector between them), as well as the points where the voltages V1 and V2 (and GND) are measured.

The red points mark cells with less than 19Ah capacity at 20A (1.1V cutoff) before reconditioning.

The black points mark cells which show swelling.

All cells with less than 19Ah initial capacity show swelling and the vast majority of them was located in the lowest of the three layers.

The harness for the stock BMS is shown below. (click thumbnails to enlarge)

It contains 6 temperature probes and the V1, V2 and GND cables. There is a second similar harness without voltage sensors for the front battery.

So far I have not been able to devise a way to re-assemble individual cells once the modules of 9 or 8 cells have been taken apart. Therefore I might have to be content with re-shuffling modules rather than cells.

Can you think of any potential problems that this approach / modification might cause?

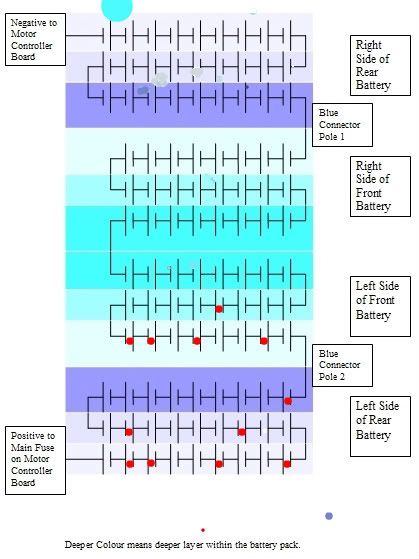

The new cell distribution would look like this:

Any help in evaluating this design would be much appreciated!

Hi Mik,

One thought would be, if you move all the bad cells to one location, is there an issue of overheating during charge? I'm not sure once a cell is damaged does it generate more heat during charge or discharge? If so then maybe putting the bad cells together would make a hot spot in the pack. Also, can you zoom in on one pack? I dont understand when you say you cannot move the cells. Are the cells physically welded together or something?

Hi Mik

Did you check the pack as total before. I bet they were all the same volts

They put low cell with high cells so the packs are even. that way they all get about the same charge and temp when charging. if you really what a better battery , do like the rc guys do buy cases of cells take the best and sell the rest to some other poor sap.

Happy riding Herb

Just a thought, but you mentioned most(?) of the weak cells were in the bottom pack; perhaps that pack gets hotter than the others, for whatever reason, leading to eventual cell failure; so if you move your good cells there, they may be impacted negatively by the same factors.

Thanks!

I thought of the heat issue, but did not want to make the initial post all too long.

The reduction in heat dissipation - due to aggregation of cells which are prone to heating - is potentially a problem, but could also be an improvement.

I do not fully understand what causes the irreversible ageing damage during heating up.

Single cells without a temp sensor might actually get hotter than a block of them, because the Vectrix BMS monitors battery temp and turns on fans or even stops charging if the temperature gets too high( >45dC).

A bunch of hot cells would not be missed as easily as the same number of heating cells spread out through the pack.

I do not know if the power delivery and/or top speed would be limited when high discharge currents cause heating of the cells. But the BATHOT and temp warning sign would come on.

The low capacity cells are (interestingly!) not distinguishable to me from "good" cells in regards to internal resistance values. I am still running further tests to clarify this, though, and might have to change this statement later.

If their internal resistance is similar to that of strong cells, then no excessive heating would occur in the weak cells during riding until they are beginning to be reversely charged; and that should of course be avoided.

During recharging the weak cells heat up if they are full before the charger stops putting current through the string. If this current is higher than about C/10 = 10A, then the gasses produced in the process cannot recombine (in an exothermic reaction) as fast as they are being created, and this causes both heat and pressure to build up.

But, this state of affairs should be avoided, like reverse charging, anyway. (I am working on some sort of BMS...)

Regarding the difficulties with getting the cells separated from each other:

Until today I had avoided breaking the ferrous metal band that holds the modules of 8 or 9 cells together.

I showed one of the modules to a substantial number of people in tool-shops, packaging shops, engineering workshops etc. etc. No-one had any good ideas of how to replace the metal band if it were removed from the pack.

Click on the thumbnails to have a closer look at the problem:

It is indeed a bit tricky, but I'm sure there is a way to do it.

I'm working on it, now that I have created a fact - the fact that one of the Vectux battery modules needs a new gizmo to hold it together...

This information may be used entirely at your own risk.

There is always a way if there is no other way!

The old Ovanic battery cells used in the GM EV1 were held together in modules of eleven cells. The band used was same material used for metal strapping in packaging large boxes. I don't know if you could get the tool into place on this battery to apply the crimp, but it was done on the Ovanics. Also (on the Ovanics) it was possible to push one cell out of the module without breaking the band. At that point the rest of the cells could be removed. Upon re-assembly the final cell was again pressed into place. Could this work on the Vectrix?

It's thicker than packaging bands and has no crimp.

There is next to no space to get any tool in to tighten the strap.

One engineer said it is not tightened much at all - on the long sides it can be pulled out a millimetre or so.

Now that I have taken one off I think that this band was not applied with a tensioner and a crimper, but rather the holes were punched into a band which was bent into the appropriate rectangular shape before being put on the module.

It might be possible to push out single cells, I need to closely look at it again with that in mind.

It's a complex piece of plastic spacers and pressurised, thin walled cells....need to proceed with caution!

So far the cells are held together with hose clamps which I applied before removing the original band.

Once I get around to taking the cells apart (no reason not to do this, now the band is gone anyway, except current lack of time) I will certainly be able to tell if single cells can be removed without taking the band off!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Thanks, spot-on, covered here: http://visforvoltage.org/forum/5052-uneven-distribution-weak-vectrix-cells-within-battery-pack-why

I intend to apply heat reflective paint to the underside of the Vectux before I re-install the battery.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Sorry, but you got this one all wrong!

Matching cells involves selecting similar cells, not dissimilar cells that cancel out each others different voltages.

In addition, "the open voltage of NiMH cells is a poor indicator of charge level";

I read that a few times during my meanderings, but nothing beats watching cell after cell bouncing back from slow, controlled, deep discharges to over 1.1 or 1.2V again within a few seconds.

Oh, maybe the initial open voltage test (repeated once to be sure to be sure) performed by me before any other tests on the cells beats it, after all, because some of the best cells had lower open voltages than some of the weakest cells!

Even internal resistance testing does not help to find the low capacity cells.

But you can find every single one of the badly affected ones in the dark because they bulge by 1mm to 2mm laterally. Easier felt than seen, but almost as good as proper capacity testing! And more than 1000 times as fast!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Cool

I would not know how to match. I Just know when you match good ones you get better battery packs.

Happy Riding , Herb

The individual cells can not be removed from the modules without taking the metal band off.

Using hose clamps the module can be re-assembled and helt together firmly whilst tying the band together with wire. I think it will last! The length of the module is slightly increased that way, but it fits into the plastic housing bending it just a tiny little bit!

It is very tricky work and definitely not recommended to do unless you have to!

But now I can re-arrange the cells at will and design a targeted BMS that looks after the cells that need it, whilst keeping costs low and voltages safe.

Check out the photos for details, click to enlarge.

Important: Remove the inter-cell connectors first to reduce the risk of shorting the cells with hose clamps or other metal objects. They could get welded to the cells and you'd be watching your cells self destruct. Wear eye protection just in case.

So, back to my main question in this thread:

How is the Vectrix stock-BMS going to behave when the weak cells are concentrated in one of the three voltage-monitored segments of the series?

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Howdy Mik,

that is quite a challenge you have there.

I would agree that the heat is definitely to blame for all you troubles, Hence the bottom cells being most affected as you noted.

Regarding your battery rework I don't see any problem with your new proposed cell arrangement, the idea being to get those already damaged cells in a place were they will get better cooling to prevent further degradation.

One suggestion would be to prioritized the temp sensors location to the bottom and damaged cells if you can.

If you plan on rebuilding modules I would recommend cycling the individual damaged cells on a bench by doing controlled power cycling (around 1/C deeply discharging and then recharging the battery several times). This would help recup some of the lost capacity.

Good luck with the rebuild

Eric

PS: adequate strapping of the cells is key to maintaining good battery performance, so unless you absolutely have to like Mik, don't try this at home.

07 Vectrix, Vego 600 mod.48V 800W, Arcade Alu E-Cycle 24VSachs Hub

Thank you for your feedback, marsupi, much appreciated!

Moving the damaged cells away from the bottom layer is only one part of the plan.

I intend to remove the heat from the bottom layer (after measuring it first once the weather is hot again here) via "It's so cool" heat reflective paint. And I plan to place other cells in the bottom layer when I re-assemble it all to test if they last there or not. Maybe it's something other than the heat; that is in my opinion an unlikely possibility, but it has not yet been conclusively excluded. Running good cells in the bottom layer will help clarify it.

The idea, as in the main idea of the re-arrangement, is to force the stock BMS to "see" the capacity imbalance much more easily because the weak cells are concentrated within one of the three segments which the stock Vectrix BMS monitors for voltage.

That segment of 27 cells will drop in voltage quite significantly once the weak cells are empty. During recharging the voltage should also rise before the rest of the pack.

There are 2 stock temp sensors on each level in the two batteries. (12 all up).

They are located on the center cell in 9-cell modules and on cell 4 or 5 in 8-cell modules. I intend to move all the weak cells into the first 27 cell section, and the three weakest cells into the 3 center positions, so they will have the stock temp sensors on them.

I am not sure what you mean with "1/C". I have been reconditioning the cells for almost 2 months now. Teeedious! And it's not even finished!

But I am coming close to some conclusions about what a good combination of discharge current and cut-off voltage for these cells is to achieve re-conditioning.

I get between 8% and 18% capacity increase (20A to 1.1V cutoff level) with the reconditioning procedure. Check at http://www.endless-sphere.com/forums/viewtopic.php?f=14&t=6277&start=0&st=0&sk=t&sd=a for more details.

The straps are indeed needed, but I am not sure how much, yet. The proof (in the pudding) will be when I open up those modules with multiple swollen cells in them. It might be impossible too close the metal band up again. Maybe I can somehow measure the tension of the metal bands on different modules before opening them up. I cannot feel a difference with my bare fingernails , yet!

Even if adequate strapping turns out not to be key to battery performance, it certainly is key to getting the cells back into the box. There are only a few mm "play" available! It's all very complex and tightly engineered.

And without adequate strapping the connectors between the cells would suffer because they are engineered to conduct current, not to prevent bending and vibration, expansion and contraction.

I am working on some diagrams which hopefully make the cell-re-shuffle clearer and will hopefully post them soon.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Well, here it is, hopefully accurate but so far preliminary....

http://www.endless-sphere.com/forums/download/file.php?id=15223

http://www.endless-sphere.com/forums/viewtopic.php?f=14&t=6853#p108629

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Sorry I meant "less then 1C" (i.e. "C" being 30A from the 30Ah battery rating, you probably knew that)

And you are already doing the reconditioning, my bad...

That's some great data by the way.

07 Vectrix, Vego 600 mod.48V 800W, Arcade Alu E-Cycle 24VSachs Hub

This thread has been added to the Vectrix Collaborative Handbook, please stay on topic!

The thread contains a fair bit of outdated / wrong information, be careful!

This information may be used entirely at your own risk.

There is always a way if there is no other way!