Today it's raining cats an dogs in Barcelona. When I was reaching home, happily protected by wonderful goretex clothes, vectrix's Temp and battery's display leds started flashing furiously. After a while I tried to recharge, but few seconds after plug-in the charging is halted by the electronics.

The display temperature stays at 21c = this is the zero starting vale, it does not mark a temperature at all. Could be that a temperature sensor is interfered by water?

If you listed carefully at the video you'll only listen one impeller fan starting. My vectrix always turned on the two impellers, the second started after the first, after a small time delay.

Has anybody experienced something like that?

Thanks!

My impellers don't always start one after another. Sometimes they start together and sometimes one after another. I can't find why it does that.

I have had the problem with the battery warning and temp light flashing after washing the vectrix a couple of different times. However, I did not try to charge it until the scooter dried out and the warning lights went out. I think Mik has posted something about this before about one of the battery temp sensors is affected by water showing a difference between it and the other sensors that turns on the warnings. I would assume after your scooter dries out, things will be back to normal.

yes, after some hours the flashing lights turned off and charging started normally. Thanks for your answers!

This happened to me a few times on the old software.

Never happened again.

I think I was just guessing that the front battery temp sensor board might get water affected due to it's location. But I never had any actual problems with it. Others pointed out the holes in the fram which need to be closed to protect that temp sensor board. But I think R has already done that.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Hehe this was one of the "onedayi'lldothat" thing that a still haven't done. What a shame....

I must close that frame holes as soon as possible... before next rain.

Yes, do that. My dealer's repair engineer did plug those two holes in the frame during the repair in July. He duct taped it.

I have had the same problem all through the long cold and WET Tassie winter this year.

The battery packs have been out twice to clean and seal up the battery management cards. Have also sealed up the offending frame holes.

Problem still occurs following a ride in driving rain...... As has been pointed out, when the V dries out, then all is well.

Suspect one or more temperature sensors may need sealing. Sigh. Packs out again.

The only option for me for now is to leave the V at home on those very wet days.

I hate driving the car, but have been caught short several times with the V refusing to charge and needing a lift home with family and friends on wet days.

Summer is almost here now, so V is reliable again for the next few months.

Paul

Paul. What are you using for the inrush curret limiter before reconnecting the packs?

You sealed the holes and there is still water problems? how strange.. where does this water come from?? I'll think about it...

Well volts76 I have nothing to prevent inrush current.

No problems so far, but I plan to install a set of auxiliary plug and socket sets and current limiting resistors next time the battery packs come out.

As for the water and frame holes issue, the normal battery bin air cooling vents will admit wet air in very wet weather. There are even small drain holes in the battery bin to allow drainage.

With spray from the tyres, cooling air vents, holes in the frame and such, it seems to me that it's very hard to keep wet air from entering the battery bin.

Even the electronics behind the fairing, including master controller, charger and even the dashboard may get internally damp in bad weather, frankly it suprises me that we are all not experiencing more wet weather problems.

Paul

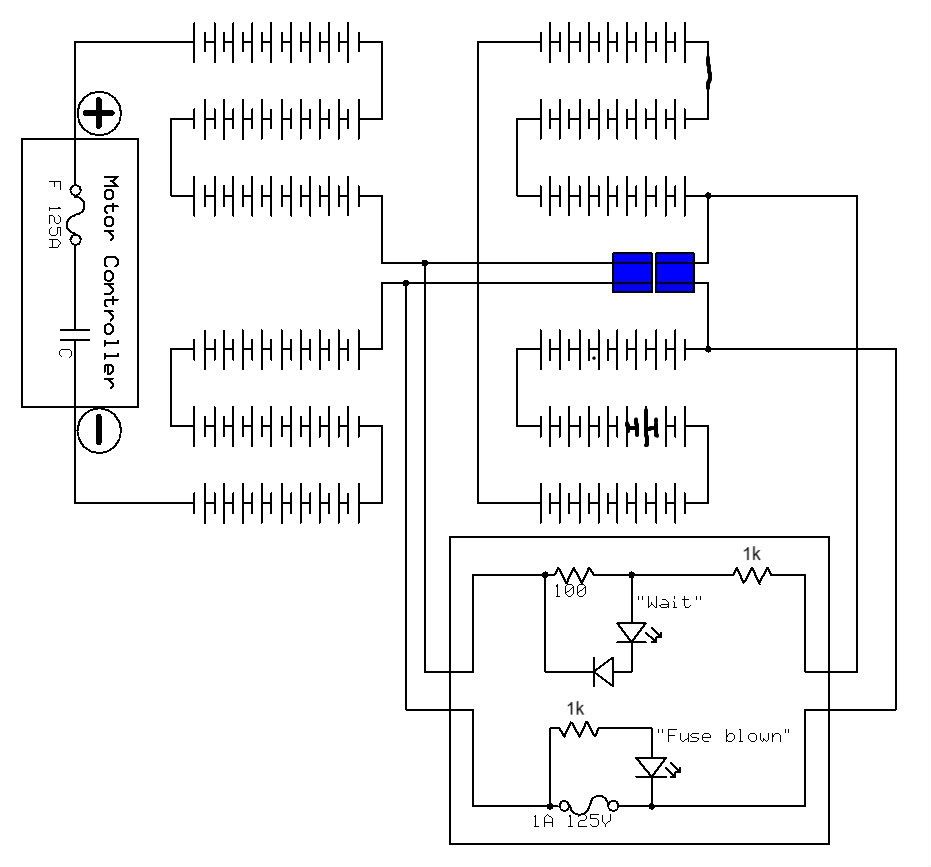

ICL easy to make. In the pics the resistor at upper right is 100 ohms. The other 2 are 1000 ohms. There is a 1 amp 125 volt chassis fuse lower right and a diode upper right. The D1 LED (upper) is the "WAIT" indicator.

There's another way that water gets in. between the battery main cover and the fan impelers cover there's the sensor temps connector. There's a huge hole at the end of the battery main cover where water wets this connector. If water traks any wire to the sensor temps, it can make it fail. Don't worry if you dn't undertand, 'll post some pictures.

Hey Volts76, any chance of publishing a drawing of the circuit for your inrush limiting device?

Paul

Just look at them there: http://visforvoltage.org/book/ev-collaborative-hand-books/7099

This information may be used entirely at your own risk.

There is always a way if there is no other way!

The water getting inside to the temp sensor...

This is the hole where the water gets in, and wets the sensor's connector. From the connector the water can go down following the wires and may reach a board temperature sensor inside the battery...

In my opinion the connection method shown here is sub-optimal.

The two ends of the Andersons connector should remain free, so that they can be put together when the ICL is still connected. The voltage of the capacitors falls immediately when the ICL is disconnected, resulting in a renewed inrush current. It can easily take a few seconds between disconnection of ICL and connection of the Andersons, particularly if the air seal is in place, because t makes it a bit tricky to grab the front Andersons properly!

This video shows how quickly the voltage across the capacitors drops again, causing an inrush current just a few seconds after disconnection of the ICL.

This information may be used entirely at your own risk.

There is always a way if there is no other way!

May I suggest to move the subject over to the handbook, so it can be found later on?

I have started a new page: http://visforvoltage.org/book/ev-collaborative-hand-books/7771

Anyone could use the "ADD CHILD PAGE" button to open a page for this particular ICL and then update as we work out how it works.

I'll throw in a schematic once the page is up!

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Sorry for the bad picture. It is suppose to show the ICL connected to the front battery terminal bolts. And connected to the cable ribbon with peircing clamps. This is done BEFORE the andersons are connected. When the "WAIT" light goes out, it is safe to reconnect the andersons. No need to rush. The ICL connectors do not interfere with connecting the andersons.

Have you considered selling these ICLs on eBay? I'd love to purchase one.

If you don't have access to an ICL or the time to build one from the schematics above, you can create a quick-n-dirty one with two 1000 Ohm resistors (at least 2W). (This cost me less than $1USD at Fry's Electronics.) Just connect the terminals from the front and rear packs through the resistors and measure the voltage across either resistor using a multimeter. When the voltage stabilizes, connect the Anderson. There's no 1A fuse for protection, but your multimeter is effectively serving the same purpose as the WAIT LED.

By the way, Mik is absolutely right about the keeping the Anderson connector free. You should be jumping from the front battery pack terminals (through the front inside holes in the black plastic battery pack enclosure) to the ribbon cables to the rear battery pack. That leaves the Anderson unobstructed when you go to reconnect.

Well, well, no-one wants to start a Collaborative Handbook page.....but here is the schematic, anyways:

This schematic shows what the fuse in the original Vectrix ICL is for. The fuse will blow when the ICL is incorrectly connected like in this diagram:

The "wrong" end of the cells in the front battery are easier to reach than the correct ones, so be careful! With Magendanz' setup (= a 1K resistor in each cable) there would be only a few mA current, but with a straight cable one cell can get shorted and destroyed.

.

.

Here is the schematic showing the correct way to connect the ICL:

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Eyeinthesky's recent drama (frying the IGBTs) has shown another good reason to use an ICL which gives feedback (that the capacitor charging is finished).

Simple resistors will work as ICL, but if there is a short which caused the fuse to open, then you will still get a nasty big spark when you connect the Andersons! That is because with a short somewhere, the capacitors will never be charged and the ICL does nothing useful.

A light globe as ICL will remain lit if a short condition is present in the IGBTs, thus showing you that the Andersons connector must not be connected!

.

.

This thread has been added to the Vectrix Collaborative Handbook, please stay on topic!

This information may be used entirely at your own risk.

There is always a way if there is no other way!