1300km since installation of the Bussman fuse.

1580km since the second MC board repair.

1918km as the Vectux.

4406km total with this scooter.

5800km on both scooters combined.

All running well now. I even gave the Vectux a bit of a wash...

Had "Test Tags" put onto charging cable and extension chord by an electrician so that recharging at work is hopefully fully compliant with workplace health and safety and other rules etc.

Both tyres will need to be replaced soon, 3mm tread depth left in the middle. The many simulated emergency breaking sessions have taken their toll, I guess.

Sissi-lines now almost at the edge of the tyre...

Mr. Mik

This information may be used entirely at your own risk.

Have been following your many excellent posting on the Vectrix , particularly interested in their 102 cell NiMh batteries pack . Very surprised to not find BMS or at least some cooling system on that many cells , very sure that the next generation pack will have sophisticated temperature management ( would have expected Vectrix to learn from the Prius power pack how to handle the temperature situation, which is the # 1 battery killer .Temperature is directly related to impedance

You have done a excellent job documenting the electronic and batteries, would have expected Vectrix to treat you with far more respect

then I have read on the many posting , maybe you should consider writing a book detailing all the chain of events , pretty sure it would be

well received , particularly now that their sale is increasing exponentially

My experience is dealing with dealing with Ni-Cad , NiMh and now Ni-Zc over the past 40 years in high power application portable lighting used in Newsgathering ( TV network ) fire dept lighting , those load vary from a low of 300 watts to as high as 2000 W , all the power pack are very high cell count from 24 to 300 cells and all high C (1C to 10C ) discharge rate .

The most significant measurement that tell me a power pack condition is impedance measurement .

When measuring individual cell impedance in a large array,have found that the lowest impedance cell will likely have the highest capacity , inversely a high impedance cell will have least capacity .

In properly charged high cell count pack , all the cells impedance should be within 10-20% ( that is after a long cooling off time to allow all the cells to reach same temperature after charging has stop) Have found that even if you assembled 100 cells with matched cells of 1% capacity variation ( best production variation is around 10% (the Japanese ones) , the chiness could be as high 30%)after as few as 10 deep charge/discharge cycles the cell capacity will start to diverge .

As the capacity of cell changes , a situation will occur when the lowest capacity cell will be driven into reverse charge by the other cells when the whole pack is discharged to low level .

This reverse charge further lower the capacity of that cell and worst yet it also increase the impedance of the cell,which now when recharged , this cell voltage will rise very fast as to make appear to be fully charged , and misleading the charger to incorrectly shut down .

Read some posting by member wondering about the condition of their pack ." Vectrix low battery blues "

I highly recommend that anyone trying to determine the condition of their power pack , get their hand on a impedance meter and record the impedance of the pack and preferably the individual cell .

A voltage test under load is a marginal test at best that it take time,it change the battery state of charge , will not tell you the battery efficiency ( how much power do you loss on charge and discharge condition ) . Impedance is a real indicator of efficiency , which I would think is the most important parameter when dealing in energy storage,transfer and conversion .

Do not understand the amount of attention send on chemistries, volt,amp/hours, weight ,# cycle etc ,when batteries are discussed and rarely if ever IMPEDANCE or Thermal management is measured or even mentioned

Toyota has the highest realiabity battery pack manufactured for the EV ,is it a coincidence that they are using the lowest impedance cells combined with the most sophisticated thermal management ?

The point of this posting is to make everyone aware of the importance of IMPEDANCE I realize that it is difficult to measure , but far easier and quicker than amp/hour and # cycle measurement

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Hi

Do you know the recall on Vectrix was for bad connetion between cell , not pack be the cells in the pack . I do not Know if Mik has got that changed yet. it may give him some odd reading because of that. also Mik are you the only one still having the charger go from full charging to parshal and back to full charging during charge cycle . a lot of the first bikes did that . Not shore if it would be related .

Appreciated your comments on the defective intercell connection , confirmed what I have been saying all along , when faced with testing a batteries of any type to determine state of charge or condition ,

Always do a voltage and impedance measurement since voltage on a cell or batteries is meaningless if it has high impedance .

High impedance cell is useable for hearing aid application over several weeks , not for EV application .

Routine impedance measurement on a EV power system will detect any potential weak link in batteries,cell,interconnect,contact etc,which come about from cycling the pack, any heat creation affected the mechanical connection because of expansion and contraction of different material,over time the connection becomes worst , impedance measurement will catch it .

SO AGAIN IMPEDANCE IS THE ANSWER !

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Thank you for your contribution, much appreciated.

Hi Mik

Have been following your many excellent posting on the Vectrix , particularly interested in their 102 cell NiMh batteries pack . Very surprised to not find BMS or at least some cooling system on that many cells , very sure that the next generation pack will have sophisticated temperature management ( would have expected Vectrix to learn from the Prius power pack how to handle the temperature situation, which is the # 1 battery killer .Temperature is directly related to impedance

I am aware of the temperature problem, hence my attempt to improve the battery cooling system which is already standard in every Vectrix. I call it the ABCool 12V power supply .

As far as I can tell there are 12 temperature sensors between the 102 battery cells, but no cables other than the temp sensor and main plus and minus cables go into the battery.

Would a BMS for Ni-MH need cables to individual cells? How is the setup in the long-lived RAV4 Ni-MH BMS???

The most significant measurement that tell me a power pack condition is impedance measurement .

When measuring individual cell impedance in a large array,have found that the lowest impedance cell will likely have the highest capacity , inversely a high impedance cell will have least capacity .

How can I do this, assuming I will take the 102 cells apart? How long does it take per cell?

Read some posting by member wondering about the condition of their pack ." Vectrix low battery blues "

Been there, done that, waiting anxiously for more replies!

I highly recommend that anyone trying to determine the condition of their power pack , get their hand on a impedance meter and record the impedance of the pack and preferably the individual cell .

Once I have identified a "bad" cell, if there really is one, how can I create a matched replacement for it from generic parts?

Mr. Mik

This information may be used entirely at your own risk.

I am aware of the temperature problem, hence my attempt to improve the battery cooling system which is already standard in every Vectrix. I call it the ABCool 12V power supply .

As far as I can tell there are 12 temperature sensors between the 102 battery cells, but no cables other than the temp sensor and main plus and minus cables go into the battery.

Would a BMS for Ni-MH need cables to individual cells? How is the setup in the long-lived RAV4 Ni-MH BMS???

Happy to see that you have a good handle on the temperature problem it is very serious and has to be resolved in order to get any decent life out of the batteries .

BMS to me mean battery management which entail monitoring each cell, mean one small gage wire going to the cell .

The BMS then determine when to charge and allow discharge .not when the temperature sensor ( it is too late by then ) The ideal BMS look at the charging voltage profile and when it sense the appropriate DV/DT for a cell remove the charging current through that cell only , it is doable , but not cheap .

How can I do this, assuming I will take the 102 cells apart? How long does it take per cell?

No you can take impedance measurement the way the pack without removing any cells .Kelvin measurement will allow you to use small leads and just clip on each cell post , you could run through the entire two packs as you have posted pictures off in less than 10 minutes ( that is recording the figures on paper) with someone helping this could be done in 5 minutes .

Once I have identified a "bad" cell, if there really is one, how can I create a matched replacement for it from generic parts?

Bad cell can mean one of the following , A) internal partial shorted cell impedance 50% less than the average impedance which I would not worry about since it will not impede the discharge current and have a insignificant effect on charging , will create less heat than a normal cell . that will not provide much power since it will self discharge and have may have lower capacity .result you have 1% less power capacity than before . B)Shorted cell , very low impedance 10% of the other one , would not worry about it for the same reason I gave before . C) Cell with a high impedance will do the following .lower the battery voltage available from the other good cells ( voltage drop is determine by the current and the cell impedance ).But far worst situation is the heating affect by the power loss in this cell will trip the thermal sensor and quickly turn the system off. No more power available out of 95% good pack that is a no no in my book.

It that case I recommend that you short out that one cell . yes you will have less power , the charging profile may be affected a little ( I would be not concerned about losing up to 5 cells )your controller LVO ( low voltage cut-off )will determine how many cells you can take out of the circuit ,taking cells out have the benefit of charge and discharge cycle not creating heat which will further damage the other good cells .

How to find and replace the defective cells ? , would not concern myself until you reach the controller LVO ( low voltage cut-off ) since you are only loosing available power . Beyond 5 % or more you have to either get cell from Vectrix ( believe that they will gladly give them to you to keep you quiet or sell them to you , if not , believe that with a little effort similar packaged cell can be found .

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Bad cell can mean one of the following , A) internal partial shorted cell impedance 50% less than the average impedance which I would not worry about since it will not impede the discharge current and have a insignificant effect on charging , will create less heat than a normal cell . that will not provide much power since it will self discharge and have may have lower capacity .result you have 1% less power capacity than before . B)Shorted cell , very low impedance 10% of the other one , would not worry about it for the same reason I gave before . C) Cell with a high impedance will do the following .lower the battery voltage available from the other good cells ( voltage drop is determine by the current and the cell impedance ).But far worst situation is the heating affect by the power loss in this cell will trip the thermal sensor and quickly turn the system off. No more power available out of 95% good pack that is a no no in my book.

It that case I recommend that you short out that one cell . yes you will have less power , the charging profile may be affected a little ( I would be not concerned about losing up to 5 cells )your controller LVO ( low voltage cut-off )will determine how many cells you can take out of the circuit ,taking cells out have the benefit of charge and discharge cycle not creating heat which will further damage the other good cells .

How to find and replace the defective cells ? , would not concern myself until you reach the controller LVO ( low voltage cut-off ) since you are only loosing available power . Beyond 5 % or more you have to either get cell from Vectrix ( believe that they will gladly give them to you to keep you quiet or sell them to you , if not , believe that with a little effort similar packaged cell can be found .

Thanks, I think I understand what you mean, but I fear the opposite of what what you say might actually happen....

The Vectux charger appears to take the voltage as the cut-off point to stop charging after aBaLPoR. In other words, it charges at full power until the total voltage reaches 150, 151, 152 or 153V (not sure why it fluctuates, probably depending on temperature).

So if one or more cells were shorted and/or removed, all the remaining cells would be over-charged after a BaLPoR. When this happens then the temperature might rise to about 45°C and then the charger will put in a "tr" cycle to cool the battery down without much charging.

153V/102 cells= 1.50V/cell

153V/101 cells= 1.515V/cell

153V/100 cells= 1.53V/cell

But I just observed the second charge after a BaLPoR, and it is back to it's usual behavior: The voltage rises to only about 145V, battery heats up to only 4°C above ambient temperature.

Mr. Mik

This information may be used entirely at your own risk.

I would be very suprised to find Vectrix using voltage set point to determine the full charge state .Most likely they are looking at DT/DT (rate of temperature rise over time ) first , then DV/DT ( rate of voltage change over time )T max ( max temperture ) and even amp/hour , using voltage trip point is a very poor indicator of NiMh cell state of charge , since it is dependend on internal impedance , current , temperature and age .

Does Vectrix give any indication in their manual what they use to determine full charge status ?Recommend that if you really interested in finding out the charging method of the batteries, hook up a chart recorder ( like a Yologawa Hybrid series HR 1300-2300 or any other ) preferably multiple channels and monitor several cells voltage , temperature and current to the pack .

You will be able to learn a lot of what is going on during charging,and realize the importance of measuring the

internal impedance of those cells, since it is the I X R (current time impedance) which determine voltage scross the cell and I X V = W ( amp time volt = watts )and in turn heat or loss . Also fairly sure that you will find a different charging profile with the scooter battery cover on and when it is removed , they designed the system with the batteries pack cover , the temperature will be far different and so will the charging curve ,a chart recorder is almost as valuable as impedance meter when working with batteries,a DMM is ideal to determine if their is power present .

Regards

Andre

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Voltage is only one of several safety charging cutoff parameters.

It will stop when the total pack voltage hits 149V to 153V, or if the highest cell temp gets above about 45°C.

The high voltage is usually only reached after a fuse replacement (much worse) or a BaLPoR (milder). I think it is a safety feature for when the electronics get it wrong and the battery is much fuller than it expects.

It then goes back to 15min of trickle charging with fans running, then tries again. This is repeated four times as far as I can tell.

The milli-ohm-meters appear out of my price range for the moment...

If I get a few hundred bucks together I would rather spend them on CanBus equipment, that might shed much more light on what is going on and involves no heavy lifting and handling bits and pieces with dangerous voltage!

For now, as lesson learnt, I have reprogrammed the ABCool 12V power supply timers to optimise cooling in the context of daily recharging at work and at home.

Keeping the charging cycles shallow and avoiding BaLPoR's with the resulting overheating during the next charge appears to be the most life-prolonging approach for the batteries for now.

The charging/cooling pattern below might need small adjustments after observing if it works as expected.

The main change to the previous settings is that the recharge at home is done in a single session after a few hours of cooling.

The previous approach (of charging just before taking off to work in the morning) is better if I cannot recharge at work, because it avoids spontaneous discharge time from occurring and might increase range slightly. It therefore prevents daily deep cycling and frequent BaLPoR's (if I add a few km's for shopping etc), at least to a degree.

Because with recharging at work only half the battery capacity will be needed before the next recharge, it is probably better to fully charge in the evening, then ABCool for a few hours, and then start the day with a cooler battery.

In the absence of range problems keeping it cool is the main concern!

Timer 1 = Vectux charger:

2000 to 2300 Mo - Su

1000 to 1230 Mo - Fri

Timer 2 = ABCool:

1630 to 2000 Mo - Su

2200 to 0100 Mo - Su

0750 to 1000 Mo - Fri

1200 to 1430 Mo - Fri

Mr. Mik

This information may be used entirely at your own risk.

Mik

You are correct in focusing on cooling the batteries.You cannot do any damage,would be little apprehensive about changing to much the thermal characteristic of the batteries pack .It will affecte charging time and by the same token the energy going to the batteries . I would assume that Vectrix did their homework in designing the charger ,taking into account the thermal characteristic of the pack,by changing it,you will affect the charging profile to some extend, question is ? ,is it for the better or worst ? /b] . Did you find anything in their manual pertaning to charging method , like CC/CV DV/DT A/H or anything to shed some light on the charger trip point ?

Only went into the impedance discussion because I thought you had mentioned that you may have defective cells in the pack , guess I was wrong !, sorry about taking your time .

Regards

Andre

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Hi Mik

I know your waranty is void . But that has nothing to do with the recall on the Battery . they should replace it for you .

As now you seam to have fixed the connection from the battery to the board / charger.

or that may still be giving you a weak contact and a temp issue in charging .

Did Andre Know of the Issue you had with the Board and would that matter to some of his advice.

As I know have miss thing on some of these threads .

Hi Mik

Andre said temp was part of the charge . were you the one that had diconected the loud cooling Fan ? I thought I saw that some one had . Just a thought.

Mik

You are correct in focusing on cooling the batteries.You cannot do any damage,would be little apprehensive about changing to much the thermal characteristic of the batteries pack .It will affecte charging time and by the same token the energy going to the batteries .

[b]I would assume that Vectrix did their homework in designing the charger ,taking into account the thermal characteristic of the pack,by changing it,you will affect the charging profile to some extend, question is ? ,is it for the better or worst ? /b] . Did you find anything in their manual pertaning to charging method , like CC/CV DV/DT A/H or anything to shed some light on the charger trip point ?

Only went into the impedance discussion because I thought you had mentioned that you may have defective cells in the pack , guess I was wrong !, sorry about taking your time .

Regards

Andre

The charging characteristics are not at all changed by the ABCool. That is, if you waited days for the batteries to cool down spontaneously before starting to charge.

As soon as the Vectux electronics switch on the 12V power to the battery cooling fans, the ABCool switches off to avoid giving 24V to the fans instead of 12V.

The fans always run when the charger is on, that is standard for the Vectrix as far as I know, but I have never tested this in very low temperatures. The Vectux battery would never have gotten below 16°C or so.

All the ABCool does is help cool the battery before and after charging and after riding.

The charging process is otherwise completely unaffected.

I time it so the battery has an approximate temp of 22°C when charging starts.

.........................

The manual is almost completely useless. It's available online somewhere if you want to have a look.

You have not wasted any time, I may or may not have defective cells. It's all about figuring out why the last few bars disappear on some Vectrixes.

It is yet to be confirmed by others if the excessive heating whilst reaching 151V repeatedly is a common feature after a BaLPoR. I believe it is.

Mr. Mik

This information may be used entirely at your own risk.

I must be missing something. According to the definition:

Electrical impedance, or simply impedance, describes a measure of opposition to a sinusoidal alternating current (AC). Electrical impedance extends the concept of resistance to AC circuits, describing not only the relative amplitudes of the voltage and current, but also the relative phases. Impedance is a complex quantity and the term complex impedance may be used interchangeably; the polar form conveniently captures both magnitude and phase characteristics,

Very good question ! ,you made my day,at last some interest in impedance ! !

A battery is a very complex energy system and the only way to measure impedance is by varying current through it .either in the charge or discharge mode , fairly easy with two step DC high current example 10 A and 50 Amp, however there is a affect on the battery somewhat and some error is introduced if the measurement is not performed quickly .

The best and fastest way I have found is using a very small AC current (0.001 A) at 1 KHZ the current is so small the battery is not affected , problem come measuring this extremely low voltage change among all the noise .There are special impedance meter designed for that , such as the Agilent 4338B or its analog older version HP4328A , this meter is reference by most batteries manufacturer .

For additional info on impedance and battery , please take a look at :

Hi Mik

Andre said temp was part of the charge . were you the one that had diconected the loud cooling Fan ? I thought I saw that some one had . Just a thought.

The design fault is not only easily fixed, but also makes it half as complicated and cheaper to build. KISS!

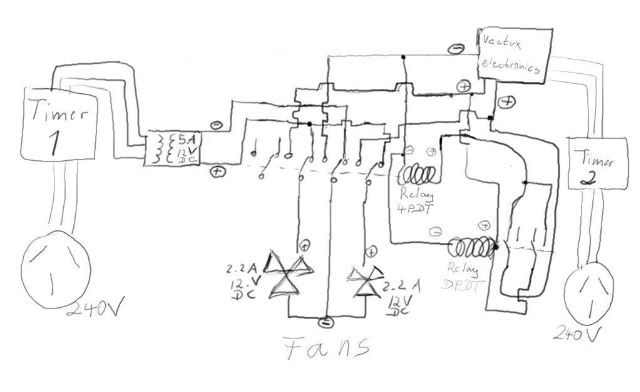

Here is a schematic of the inferior design, which is currently installed in the Vectux:

This design is unnecessarily complicated, but works well in winter....

.

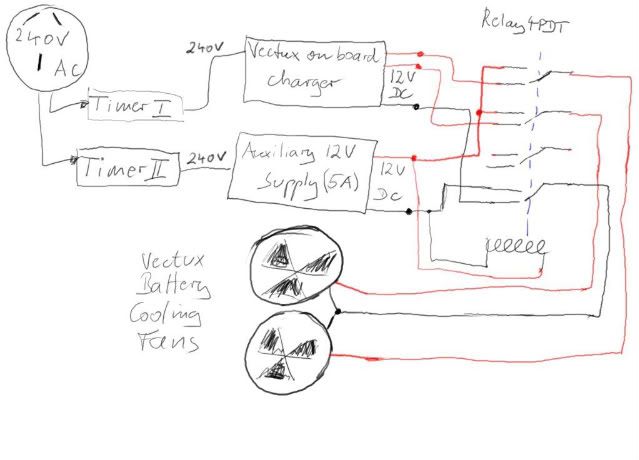

And this is the new, simpler and better design (but not built or tested, yet...):

The first problem with the first design is that the Vectux charger activates the DTDP relay, which then switches the 4PDT relay on, so that the Vectux charger electronics provide power to the fans, no matter if the ABCool is plugged in, or not. This can cause unnecessary battery depletion in very hot conditions. The second problem is that if one of the two relays fail to switch and the ABCool is not on, then the charger would run without cooling fans. This would not cause immediate severe damage, because once the battery temperature climbs to 46°C the charger will pause. This was involuntarily tested by siai47.

. The new, improved setup requires only one relay.

The Vectux charger is supplying the fans with 12V by default, even if the relay becomes faulty and fails to switch years later.

When everything is still working and the Auxiliary power supply is turned on, then the relay switches so that the auxiliary power source supplies the fans with 12V power, no matter if the Vectux charger is also trying to run the fans, or not. So mains power is used whenever available for cooling the batteries.

.

. The new design has 2 advantages over the current design:

Advantage 1): If any of the relays fail to switch, then the Vectux will function like a normal Vectrix. Currently a relay failure would cause loss of battery cooling during charging (if the ABCool is not plugged in) because the "default" position of the relays is to have the Auxiliary 12V supply switched on.

Advantage 2): Even in very hot conditions (battery and/or ambient temperature more than about 35°C (= the trigger temperature for the switching on of the battery cooling fans by the Vectux electronics), the power for the fans will be provided by the ABCool when it is connected to the mains power supply.

.

. With the first design the following scenarios are possible:

Scenario 1): The Vectux battery is hot after riding in 35°C ambient temperature; the battery fans will therefore run spontaneously when the Vectux is being parked. Even if I plug in the first design ABCool, the power for the fans will continue to be provided by the battery, not by the ABCool. This leads to further depletion of the battery and further heating of the battery. Not much, but totally unnecessarily.

Scenario 2): After charging has finished in a hot environment the battery will be so hot that the fans remain switched on by the Vectux electronics, using power from the hot battery, even if the ABCool would otherwise run the fans by using the grid without depleting and heating the freshly charged battery.

.

.

In summary (it's really the same stuff for a forth time, sorry to be a bit repetitive here...):

The first ABCool design will not allow additional cooling to be powered from the grid at those times when the Vectux electronics have decided that battery cooling is needed.

These are of course the times when cooling is needed the most and for the longest periods, and the power for this will come out of the battery, not the grid.

.

I'll post this also in my blog and will probably continue to update it there during the building and testing of the new design.

Mr. Mik

This information may be used entirely at your own risk.

Mavizen's electric bike hits 130 MPH, ships with Linux and WiFi

Mik, did you see this new open source platform?

Mavizen, the manufacturing arm of the TTXGP (the Time Trials Xtreme Grand Prix -- a race for zero-emissions motorcycles) has just announced the TTX02 at this year's SEMA. A shining example of "EVs as consumer electronics" (the buzz-concept going 'round the electric vehicle scene) this guy is being billed not as a bike, but as a development platform -- shipping not only with a chassis and drivetrain, but with an open source Linux OS, web server, USB-based system bus, and WiFi connectivity. If you're looking to give the gang from Mission Motors a run for their money at the next TTXGP, hit the read link -- about $41,000 will get you in the game. Videos after the break.

1300km since installation of the Bussman fuse.

1580km since the second MC board repair.

1918km as the Vectux.

4406km total with this scooter.

5800km on both scooters combined.

All running well now. I even gave the Vectux a bit of a wash...

Had "Test Tags" put onto charging cable and extension chord by an electrician so that recharging at work is hopefully fully compliant with workplace health and safety and other rules etc.

Both tyres will need to be replaced soon, 3mm tread depth left in the middle. The many simulated emergency breaking sessions have taken their toll, I guess.

Sissi-lines now almost at the edge of the tyre...

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Hi Mik

Have been following your many excellent posting on the Vectrix , particularly interested in their 102 cell NiMh batteries pack .

Very surprised to not find BMS or at least some cooling system on that many cells , very sure that the next generation pack will have sophisticated temperature management ( would have expected Vectrix to learn from the Prius power pack how to handle the temperature situation, which is the # 1 battery killer .Temperature is directly related to impedance

You have done a excellent job documenting the electronic and batteries, would have expected Vectrix to treat you with far more respect

then I have read on the many posting , maybe you should consider writing a book detailing all the chain of events , pretty sure it would be

well received , particularly now that their sale is increasing exponentially

My experience is dealing with dealing with Ni-Cad , NiMh and now Ni-Zc over the past 40 years in high power application portable lighting used in Newsgathering ( TV network ) fire dept lighting , those load vary from a low of 300 watts to as high as 2000 W , all the power pack are very high cell count from 24 to 300 cells and all high C (1C to 10C ) discharge rate .

The most significant measurement that tell me a power pack condition is impedance measurement .

When measuring individual cell impedance in a large array,have found that the lowest impedance cell will likely have the highest capacity , inversely a high impedance cell will have least capacity .

In properly charged high cell count pack , all the cells impedance should be within 10-20% ( that is after a long cooling off time to allow all the cells to reach same temperature after charging has stop)

Have found that even if you assembled 100 cells with matched cells of 1% capacity variation ( best production variation is around 10% (the Japanese ones) , the chiness could be as high 30%)after as few as 10 deep charge/discharge cycles the cell capacity will start to diverge .

As the capacity of cell changes , a situation will occur when the lowest capacity cell will be driven into reverse charge by the other cells when the whole pack is discharged to low level .

This reverse charge further lower the capacity of that cell and worst yet it also increase the impedance of the cell,which now when recharged , this cell voltage will rise very fast as to make appear to be fully charged , and misleading the charger to incorrectly shut down .

Read some posting by member wondering about the condition of their pack ." Vectrix low battery blues "

I highly recommend that anyone trying to determine the condition of their power pack , get their hand on a impedance meter and record the impedance of the pack and preferably the individual cell .

A voltage test under load is a marginal test at best that it take time,it change the battery state of charge , will not tell you the battery efficiency ( how much power do you loss on charge and discharge condition ) .

Impedance is a real indicator of efficiency , which I would think is the most important parameter when dealing in energy storage,transfer and conversion .

Do not understand the amount of attention send on chemistries, volt,amp/hours, weight ,# cycle etc ,when batteries are discussed and rarely if ever IMPEDANCE or Thermal management is measured or even mentioned

Toyota has the highest realiabity battery pack manufactured for the EV ,is it a coincidence that they are using the lowest impedance cells combined with the most sophisticated thermal management ?

The point of this posting is to make everyone aware of the importance of IMPEDANCE I realize that it is difficult to measure , but far easier and quicker than amp/hour and # cycle measurement

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Hi

Do you know the recall on Vectrix was for bad connetion between cell , not pack be the cells in the pack . I do not Know if Mik has got that changed yet. it may give him some odd reading because of that. also Mik are you the only one still having the charger go from full charging to parshal and back to full charging during charge cycle . a lot of the first bikes did that . Not shore if it would be related .

Happy riding , Herb

Vectrix-NH

Appreciated your comments on the defective intercell connection , confirmed what I have been saying all along , when faced with testing a batteries of any type to determine state of charge or condition ,

Always do a voltage and impedance measurement since voltage on a cell or batteries is meaningless if it has high impedance .

High impedance cell is useable for hearing aid application over several weeks , not for EV application .

Routine impedance measurement on a EV power system will detect any potential weak link in batteries,cell,interconnect,contact etc,which come about from cycling the pack, any heat creation affected the mechanical connection because of expansion and contraction of different material,over time the connection becomes worst , impedance measurement will catch it .

SO AGAIN IMPEDANCE IS THE ANSWER !

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Thank you for your contribution, much appreciated.

I am aware of the temperature problem, hence my attempt to improve the battery cooling system which is already standard in every Vectrix. I call it the ABCool 12V power supply .

As far as I can tell there are 12 temperature sensors between the 102 battery cells, but no cables other than the temp sensor and main plus and minus cables go into the battery.

Would a BMS for Ni-MH need cables to individual cells? How is the setup in the long-lived RAV4 Ni-MH BMS???

How can I do this, assuming I will take the 102 cells apart? How long does it take per cell?

Been there, done that, waiting anxiously for more replies!

Once I have identified a "bad" cell, if there really is one, how can I create a matched replacement for it from generic parts?

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Happy to see that you have a good handle on the temperature problem it is very serious and has to be resolved in order to get any decent life out of the batteries .

BMS to me mean battery management which entail monitoring each cell, mean one small gage wire going to the cell .

The BMS then determine when to charge and allow discharge .not when the temperature sensor ( it is too late by then ) The ideal BMS look at the charging voltage profile and when it sense the appropriate DV/DT for a cell remove the charging current through that cell only , it is doable , but not cheap .

No you can take impedance measurement the way the pack without removing any cells .Kelvin measurement will allow you to use small leads and just clip on each cell post , you could run through the entire two packs as you have posted pictures off in less than 10 minutes ( that is recording the figures on paper) with someone helping this could be done in 5 minutes .

Bad cell can mean one of the following , A) internal partial shorted cell impedance 50% less than the average impedance which I would not worry about since it will not impede the discharge current and have a insignificant effect on charging , will create less heat than a normal cell . that will not provide much power since it will self discharge and have may have lower capacity .result you have 1% less power capacity than before .

B)Shorted cell , very low impedance 10% of the other one , would not worry about it for the same reason I gave before .

C) Cell with a high impedance will do the following .lower the battery voltage available from the other good cells ( voltage drop is determine by the current and the cell impedance ).But far worst situation is the heating affect by the power loss in this cell will trip the thermal sensor and quickly turn the system off. No more power available out of 95% good pack that is a no no in my book.

It that case I recommend that you short out that one cell . yes you will have less power , the charging profile may be affected a little ( I would be not concerned about losing up to 5 cells )your controller LVO ( low voltage cut-off )will determine how many cells you can take out of the circuit ,taking cells out have the benefit of charge and discharge cycle not creating heat which will further damage the other good cells .

How to find and replace the defective cells ? , would not concern myself until you reach the controller LVO ( low voltage cut-off ) since you are only loosing available power . Beyond 5 % or more you have to either get cell from Vectrix ( believe that they will gladly give them to you to keep you quiet or sell them to you , if not , believe that with a little effort similar packaged cell can be found .

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Thanks, I think I understand what you mean, but I fear the opposite of what what you say might actually happen....

The Vectux charger appears to take the voltage as the cut-off point to stop charging after aBaLPoR. In other words, it charges at full power until the total voltage reaches 150, 151, 152 or 153V (not sure why it fluctuates, probably depending on temperature).

So if one or more cells were shorted and/or removed, all the remaining cells would be over-charged after a BaLPoR. When this happens then the temperature might rise to about 45°C and then the charger will put in a "tr" cycle to cool the battery down without much charging.

153V/102 cells= 1.50V/cell

153V/101 cells= 1.515V/cell

153V/100 cells= 1.53V/cell

But I just observed the second charge after a BaLPoR, and it is back to it's usual behavior: The voltage rises to only about 145V, battery heats up to only 4°C above ambient temperature.

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

I would be very suprised to find Vectrix using voltage set point to determine the full charge state .Most likely they are looking at DT/DT (rate of temperature rise over time ) first , then DV/DT ( rate of voltage change over time )T max ( max temperture ) and even amp/hour , using voltage trip point is a very poor indicator of NiMh cell state of charge , since it is dependend on internal impedance , current , temperature and age .

Does Vectrix give any indication in their manual what they use to determine full charge status ?Recommend that if you really interested in finding out the charging method of the batteries, hook up a chart recorder ( like a Yologawa Hybrid series HR 1300-2300 or any other ) preferably multiple channels and monitor several cells voltage , temperature and current to the pack .

You will be able to learn a lot of what is going on during charging,and realize the importance of measuring the

internal impedance of those cells, since it is the I X R (current time impedance) which determine voltage scross the cell and I X V = W ( amp time volt = watts )and in turn heat or loss .

Also fairly sure that you will find a different charging profile with the scooter battery cover on and when it is removed , they designed the system with the batteries pack cover , the temperature will be far different and so will the charging curve ,a chart recorder is almost as valuable as impedance meter when working with batteries,a DMM is ideal to determine if their is power present .

Regards

Andre

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Voltage is only one of several safety charging cutoff parameters.

It will stop when the total pack voltage hits 149V to 153V, or if the highest cell temp gets above about 45°C.

The high voltage is usually only reached after a fuse replacement (much worse) or a BaLPoR (milder). I think it is a safety feature for when the electronics get it wrong and the battery is much fuller than it expects.

It then goes back to 15min of trickle charging with fans running, then tries again. This is repeated four times as far as I can tell.

The milli-ohm-meters appear out of my price range for the moment...

If I get a few hundred bucks together I would rather spend them on CanBus equipment, that might shed much more light on what is going on and involves no heavy lifting and handling bits and pieces with dangerous voltage!

For now, as lesson learnt, I have reprogrammed the ABCool 12V power supply timers to optimise cooling in the context of daily recharging at work and at home.

Keeping the charging cycles shallow and avoiding BaLPoR's with the resulting overheating during the next charge appears to be the most life-prolonging approach for the batteries for now.

The charging/cooling pattern below might need small adjustments after observing if it works as expected.

The main change to the previous settings is that the recharge at home is done in a single session after a few hours of cooling.

The previous approach (of charging just before taking off to work in the morning) is better if I cannot recharge at work, because it avoids spontaneous discharge time from occurring and might increase range slightly. It therefore prevents daily deep cycling and frequent BaLPoR's (if I add a few km's for shopping etc), at least to a degree.

Because with recharging at work only half the battery capacity will be needed before the next recharge, it is probably better to fully charge in the evening, then ABCool for a few hours, and then start the day with a cooler battery.

In the absence of range problems keeping it cool is the main concern!

Timer 1 = Vectux charger:

2000 to 2300 Mo - Su

1000 to 1230 Mo - Fri

Timer 2 = ABCool:

1630 to 2000 Mo - Su

2200 to 0100 Mo - Su

0750 to 1000 Mo - Fri

1200 to 1430 Mo - Fri

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Mik

You are correct in focusing on cooling the batteries.You cannot do any damage,would be little apprehensive about changing to much the thermal characteristic of the batteries pack .It will affecte charging time and by the same token the energy going to the batteries .

I would assume that Vectrix did their homework in designing the charger ,taking into account the thermal characteristic of the pack,by changing it,you will affect the charging profile to some extend, question is ? ,is it for the better or worst ? /b] .

Did you find anything in their manual pertaning to charging method , like CC/CV DV/DT A/H or anything to shed some light on the charger trip point ?

Only went into the impedance discussion because I thought you had mentioned that you may have defective cells in the pack , guess I was wrong !, sorry about taking your time .

Regards

Andre

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

Hi Mik

I know your waranty is void . But that has nothing to do with the recall on the Battery . they should replace it for you .

As now you seam to have fixed the connection from the battery to the board / charger.

or that may still be giving you a weak contact and a temp issue in charging .

Did Andre Know of the Issue you had with the Board and would that matter to some of his advice.

As I know have miss thing on some of these threads .

Happy riding , Herb

Hi Mik

Andre said temp was part of the charge . were you the one that had diconected the loud cooling Fan ? I thought I saw that some one had . Just a thought.

Happy riding, Herb

The charging characteristics are not at all changed by the ABCool. That is, if you waited days for the batteries to cool down spontaneously before starting to charge.

As soon as the Vectux electronics switch on the 12V power to the battery cooling fans, the ABCool switches off to avoid giving 24V to the fans instead of 12V.

The fans always run when the charger is on, that is standard for the Vectrix as far as I know, but I have never tested this in very low temperatures. The Vectux battery would never have gotten below 16°C or so.

All the ABCool does is help cool the battery before and after charging and after riding.

The charging process is otherwise completely unaffected.

I time it so the battery has an approximate temp of 22°C when charging starts.

.........................

The manual is almost completely useless. It's available online somewhere if you want to have a look.

You have not wasted any time, I may or may not have defective cells. It's all about figuring out why the last few bars disappear on some Vectrixes.

It is yet to be confirmed by others if the excessive heating whilst reaching 151V repeatedly is a common feature after a BaLPoR. I believe it is.

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

I must be missing something. According to the definition:

Electrical impedance, or simply impedance, describes a measure of opposition to a sinusoidal alternating current (AC). Electrical impedance extends the concept of resistance to AC circuits, describing not only the relative amplitudes of the voltage and current, but also the relative phases. Impedance is a complex quantity and the term complex impedance may be used interchangeably; the polar form conveniently captures both magnitude and phase characteristics,

So how do you measure Impedance in a DC battery?

Robert Dudley

E-Scoot Tech

sgmdudley

Very good question ! ,you made my day,at last some interest in impedance ! !

A battery is a very complex energy system and the only way to measure impedance is by varying current through it .either in the charge or discharge mode , fairly easy with two step DC high current example 10 A and 50 Amp, however there is a affect on the battery somewhat and some error is introduced if the measurement is not performed quickly .

The best and fastest way I have found is using a very small AC current (0.001 A) at 1 KHZ the current is so small the battery is not affected , problem come measuring this extremely low voltage change among all the noise .There are special impedance meter designed for that , such as the Agilent 4338B or its analog older version HP4328A , this meter is reference by most batteries manufacturer .

For additional info on impedance and battery , please take a look at :

The virtues of Impedance Testing of Batteries

it is available on this site EV Download Library

http://visforvoltage.org/page/technical-help/399-downloadable-manuals-and-diagrams

HEAT & LOSS & INEFFICIENCY RELATED DIRECTLY to IMPEDANCE

The cable to the fans needs to be disconnected as part of the procedure to remove the battery housing cover.

Someone had asked if the fans can be turned off (in another thread), so I wrote:

I have not tested this for more than a few minutes - watch it like a hawk for at least one full charging cycle if you decide to use the 30sec procedure to disconnect the battery cooling fans......

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

I the process of observing the latest "Recharge after BaLoPoR" I discovered a design fault in the ABCool 12V power supply which causes two potential problems.

The design fault is not only easily fixed, but also makes it half as complicated and cheaper to build. KISS!

Here is a schematic of the inferior design, which is currently installed in the Vectux:

This design is unnecessarily complicated, but works well in winter....

.

And this is the new, simpler and better design (but not built or tested, yet...):

The first problem with the first design is that the Vectux charger activates the DTDP relay, which then switches the 4PDT relay on, so that the Vectux charger electronics provide power to the fans, no matter if the ABCool is plugged in, or not. This can cause unnecessary battery depletion in very hot conditions.

The second problem is that if one of the two relays fail to switch and the ABCool is not on, then the charger would run without cooling fans. This would not cause immediate severe damage, because once the battery temperature climbs to 46°C the charger will pause. This was involuntarily tested by siai47.

.

The new, improved setup requires only one relay.

The Vectux charger is supplying the fans with 12V by default, even if the relay becomes faulty and fails to switch years later.

When everything is still working and the Auxiliary power supply is turned on, then the relay switches so that the auxiliary power source supplies the fans with 12V power, no matter if the Vectux charger is also trying to run the fans, or not. So mains power is used whenever available for cooling the batteries.

.

.

The new design has 2 advantages over the current design:

Advantage 1): If any of the relays fail to switch, then the Vectux will function like a normal Vectrix. Currently a relay failure would cause loss of battery cooling during charging (if the ABCool is not plugged in) because the "default" position of the relays is to have the Auxiliary 12V supply switched on.

Advantage 2): Even in very hot conditions (battery and/or ambient temperature more than about 35°C (= the trigger temperature for the switching on of the battery cooling fans by the Vectux electronics), the power for the fans will be provided by the ABCool when it is connected to the mains power supply.

.

.

With the first design the following scenarios are possible:

Scenario 1): The Vectux battery is hot after riding in 35°C ambient temperature; the battery fans will therefore run spontaneously when the Vectux is being parked. Even if I plug in the first design ABCool, the power for the fans will continue to be provided by the battery, not by the ABCool. This leads to further depletion of the battery and further heating of the battery. Not much, but totally unnecessarily.

Scenario 2): After charging has finished in a hot environment the battery will be so hot that the fans remain switched on by the Vectux electronics, using power from the hot battery, even if the ABCool would otherwise run the fans by using the grid without depleting and heating the freshly charged battery.

.

.

In summary (it's really the same stuff for a forth time, sorry to be a bit repetitive here...):

The first ABCool design will not allow additional cooling to be powered from the grid at those times when the Vectux electronics have decided that battery cooling is needed.

These are of course the times when cooling is needed the most and for the longest periods, and the power for this will come out of the battery, not the grid.

.

I'll post this also in my blog and will probably continue to update it there during the building and testing of the new design.

Mr. Mik

This information may be used entirely at your own risk.

There is always a way if there is no other way!

Mik, did you see this new open source platform?

Mavizen, the manufacturing arm of the TTXGP (the Time Trials Xtreme Grand Prix -- a race for zero-emissions motorcycles) has just announced the TTX02 at this year's SEMA. A shining example of "EVs as consumer electronics" (the buzz-concept going 'round the electric vehicle scene) this guy is being billed not as a bike, but as a development platform -- shipping not only with a chassis and drivetrain, but with an open source Linux OS, web server, USB-based system bus, and WiFi connectivity. If you're looking to give the gang from Mission Motors a run for their money at the next TTXGP, hit the read link -- about $41,000 will get you in the game. Videos after the break.

Continue reading Mavizen's electric bike hits 130 MPH, ships with Linux and WiFi

Pages